When I first started exploring the jewelry industry, I couldn’t help noticing how quickly stainless steel necklaces were appearing across global marketplaces—from luxury boutiques to social media fashion hauls. As someone who’s handled everything from plated brass to sterling silver, I saw beginner jewelers and small brands struggling with tarnish complaints, allergic reactions, and high inventory costs. That’s when stainless steel caught my attention—it offered the shine of silver, the resilience of titanium, and the affordability of costume jewelry.

The best stainless steel necklaces combine affordability, durability, and hypoallergenic comfort. In this beginner-friendly guide, I’ll break down why stainless steel jewelry is seeing explosive growth, how it compares to plated alloys, how to ensure consistent quality for imported pieces, and what to look for when choosing an OEM or ODM manufacturer.

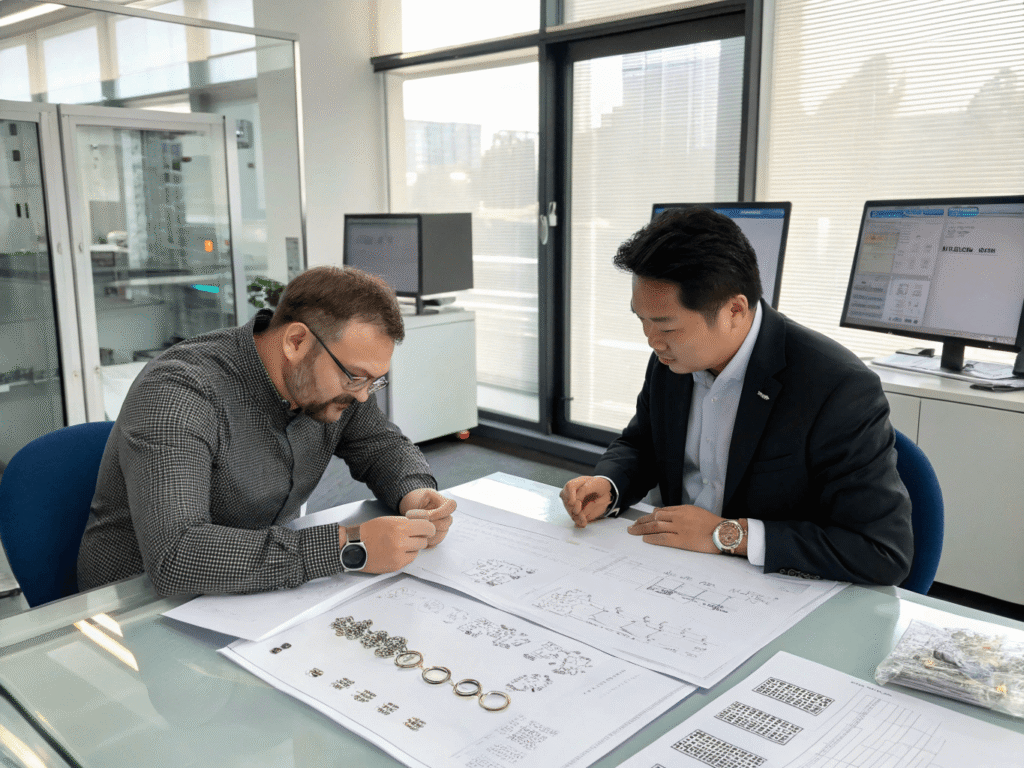

As someone who has worked directly with Chinese suppliers, I’ve learned the importance of understanding material grades, finishing techniques, and factory standards. In the sections below, I’ll share practical insights and lessons learned that can help new jewelry business owners confidently source and select stainless steel necklaces that meet both customer expectations and brand reputation goals.

Table of Contents

ToggleHow to Tell if Stainless Steel Necklaces Are Right for Your Jewelry Business

When I began assessing new materials for my jewelry line, stainless steel stood out for one major reason—its balance of value and longevity. For beginners in the jewelry business, choosing stainless steel means you can deliver a polished, premium look without worrying about rapid tarnish or skin irritation.

Signs Stainless Steel Suits Your Brand

Here’s how I knew stainless steel fit my business model:

- My target buyers wanted affordable, trendy, long-lasting jewelry.

- I needed a material that wouldn’t tarnish in humid climates or leave marks on skin.

- I wanted to minimize returns and customer complaints, especially during peak seasons.

If your brand values sustainable products, caters to daily-wear users, or focuses on accessible luxury, stainless steel might be your perfect starting point.

| Key Requirement | Stainless Steel Response | Business Impact |

|---|---|---|

| Daily wear resistance | No rust, no discoloration | High customer satisfaction |

| Trend adaptability | Works with minimalist and luxury designs | Broader market appeal |

| Price flexibility | Mid-range cost | Better profit margins |

| Hypoallergenic features | Safe for sensitive skin | Fewer complaints, stronger reputation |

As more consumers shift toward cost-effective yet durable jewelry, stainless steel has become an anchor for small businesses aiming to balance affordability with quality.

Advantages of Stainless Steel Necklaces Compared to Plated Alloy Necklaces

When I first replaced my alloy-based collection with stainless steel, the change was revolutionary. No more tarnish returns, no more color fading after a few wears, and—most surprisingly—customers reported wearing their necklaces at the gym and in the shower without any issues.

Technological Leap: The Waterproof Revolution

Traditional electroplated alloys fade fast and react to sweat and moisture. PVD plating (Physical Vapor Deposition), used on most modern stainless steel pieces, bonds color molecules at a molecular level, creating waterproof, sweatproof, and tarnish-resistant coatings.

| Feature | Stainless Steel (PVD) | Plated Alloy (Brass or Copper Base) |

|---|---|---|

| Durability | Extremely hard, scratch-resistant | Prone to dents and fading |

| Waterproof rating | Yes (sweat & shower-proof) | No (oxidizes easily) |

| Hypoallergenic | Low-allergen, medical-grade 316L | May cause irritation |

| Maintenance | Minimal (wipe clean) | Requires regular polishing |

| Eco profile | Recyclable and long-lasting | Disposable, short lifespan |

Functional Advantages

- Cost-effectiveness – Retail prices of stainless steel necklaces typically range from $30–$80, while similar-looking gold chains exceed hundreds.

- Men’s Jewelry Crossover – Stainless steel’s industrial aesthetic, combined with its heavyweight sturdiness, appeals strongly to male consumers.

- Sustainability – Fully recyclable and eco-conscious, stainless steel aligns well with modern market preferences.

For jewelry brands competing online, offering stainless steel necklaces helps position collections within that ideal “affordable luxury” category—one that sells remarkably well on platforms like Etsy and Shopify.

Ensuring Consistent Quality When Importing Stainless Steel Jewelry from China

After my first international order, I realized maintaining consistent finish and color was the toughest part of importing jewelry. Beginner brands often assume “stainless steel” guarantees quality—but not all factories use high-grade 316L or perform reliable PVD coating.

Materials and Grade Verification

Before partnering with any supplier, I always confirm:

- 316L Stainless Steel Certification – Sometimes referred to as “surgical steel,” this ensures the product won’t cause allergic skin reactions.

- Surface Polishing Level – Mirror-polished finishes provide premium shine.

- PVD vs Electroplated Process – Require visual samples and plating data sheets.

- Nickel-release testing – Essential for meeting European and U.S. import standards.

| Quality Factor | Recommended Standard | Why It Matters |

|---|---|---|

| Grade Type | 316L | Hypoallergenic, surgical-grade |

| Finish Type | Mirror or brushed | Defines luxury appeal |

| Coating | PVD gold/black/rose plating | Improves wear resistance |

| Nickel Test | <0.5 μg/cm²/week | Meets safety compliance |

Factory Audits and Sample Checks

In my experience, performing sample inspections is non-negotiable:

- Always request two finish samples from different batches to check color consistency.

- Examine edges and clasps—rough edges mean poor sanding.

- Conduct a 30-day wear test: store a sample near moisture, wear it daily, test for discoloration.

When you find a supplier who consistently passes these checks, you’ve secured a reliable pillar for long-term business growth.

Choosing an OEM/ODM Manufacturer for Stainless Steel Necklaces

When I started sourcing from China, I was overwhelmed by the number of OEM and ODM manufacturers claiming “premium quality.” Over time, I learned that selecting the right factory goes beyond competitive pricing—it depends on transparency and technical innovation.

OEM vs. ODM Explained

- OEM (Original Equipment Manufacturer): You provide design specs, and the supplier reproduces them exactly.

- ODM (Original Design Manufacturer): The supplier offers existing designs that you can brand or slightly modify.

For new jewelry business owners, ODM is the quickest route—it lets you launch collections fast and test demand before investing in custom OEM molds.

How I Assess a Jewelry Factory

- Design Consistency: Are their stainless steel samples visually uniform across pieces?

- Plating Equipment: Do they have in-house PVD plating, or do they outsource?

- Production Capacity: Ensure monthly outputs match your forecasting needs.

- Quality Control Reports: Reliable factories document systematic inspections.

| Evaluation Area | What to Look For | Why It’s Important |

|---|---|---|

| In-house PVD facility | Yes | Guarantees uniform color and durability |

| MOQ (Minimum Order Quantity) | Flexible (50–200 pcs) | Ideal for startups |

| Communication speed | Fast, responsive | Reduces lead time delays |

| Customization | 3D logo engraving, packaging | Builds brand uniqueness |

Bonus Tip

Ask for photos and videos during plating and assembly stages. Seeing actual workers handle and polish your necklaces helps verify authenticity and craftsmanship. Trust me—transparency is worth more than any low-per-unit quote.

Conclusion

When I look back at how stainless steel transformed my jewelry business, it’s clear this material solved the common “costume jewelry dilemma.” It bridges the gap between cheap alloys that tarnish quickly and fine metals that are financially out of reach.

For beginners, stainless steel necklaces represent durability, comfort, and elegance—all at an accessible price. If I were starting again today, I would begin with 316L stainless steel designs featuring reliable PVD coating and verify suppliers who pass wear tests and sample audits.

Based on experience, stainless steel isn’t just a trend—it’s a smart foundation for sustainable and profitable jewelry collections. Investing in quality materials and transparent manufacturers will help your brand earn trust and longevity in a competitive global market.