If you’ve ever opened a jewelry bead kit and wondered why there are so many different pliers, wires, or tiny metal parts, you’re not alone. Many beginner crafters—and even experienced jewelry sellers—struggle to understand which tools are essential and which are optional. For jewelry businesses or DIY artisans, choosing the right bead kit can mean the difference between a polished, professional piece and a frustrating, uneven result.

In short, an essential jewelry bead kit should include precision tools (pliers and cutters), consumable materials (wires, findings, and beads), and organizational accessories (trays or bead boards). Professional kits often expand on these basics to support customization, volume production, or brand-level consistency in design.

Whether you are a hobbyist, a retail crafter, or an OEM buyer sourcing custom kits, understanding each tool’s purpose will help you select or customize a bead kit that’s both efficient and cost-effective. Below, I’ll walk you through the key components and considerations every jewelry-making kit should include.

Table of Contents

ToggleCore Pliers Every Beader Needs

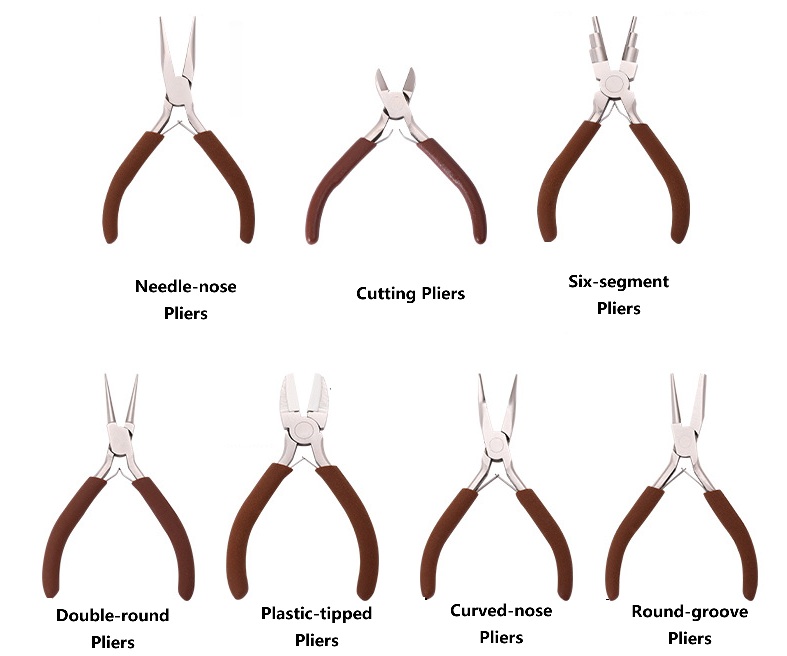

Pliers are the backbone of any jewelry kit, shaping, bending, and securing metal without damaging your components. A professional-quality kit should include at least three to four types of precision pliers.

| Tool | Function | Common Material/Build |

|---|---|---|

| Round-Nose Pliers | Ideal for creating loops and curves in wire. The conical jaws taper to a point, allowing various loop sizes. | Polished steel, non-slip handle |

| Chain-Nose Pliers | Used for gripping wire, opening jump rings, or flattening crimp beads. The interior of the jaws should be smooth to avoid marring metal. | Stainless steel or carbon steel |

| Flat-Nose Pliers | Provide a strong, flat grip—excellent for right-angle bends or holding wire steady when working with clasps. | Wide jaw, comfortable grip |

| Crimping Pliers | Specifically designed to secure crimp beads neatly around wire ends for a finished, professional look. | Double-jaw or grooved design |

Expert Tip:

Always choose pliers with a spring-return handle—this prevents hand fatigue during long production sessions, which is especially useful in bulk jewelry assembly.

Cutting & Precision Tools

A clean cut can define the quality of your finished piece. Dull scissors or rough wire cutters can cause fraying or leave sharp ends that irritate the skin.

Essential Cutting Tools:

- Flush Cutters (Wire Cutters):

Designed to cut wire cleanly against a flat surface, producing smooth edges. A flush cut is critical for avoiding scratches. - Thread Snips:

Compact, spring-loaded scissors for clean cuts on silk thread, nylon, or elastic stringing material. - Bead Reamer:

A fine, pen-style tool with a rough diamond tip, used to enlarge or smooth bead holes—critical for gemstone or glass beads that might have irregular openings.

Additional Measuring Aids:

- Ruler or Caliper: Measures bead diameter and wire thickness accurately.

- Tape Measure: Helps with bracelet and necklace length consistency, which is key in OEM or retail production.

Stringing, Layout, and Assembly Tools

Beyond the pliers and cutters, effective jewelry design requires proper layout and threading equipment to bring your ideas to life.

Layout and Stringing Components:

- Bead Board (Design Board):

A flocked surface with measurement grooves keeps beads from rolling and allows design visualization before assembly. - Beading Needles:

Flexible, narrow needles with fine eyes made for threading multiple passes through small bead holes—essential for intricate or woven designs. - Bead Scoop and Tweezers:

These allow fast handling and sorting of small beads, helping maintain speed and cleanliness in production. - Thread Conditioner (Optional):

A wax that reduces tangling and fraying, extending the life of your finished product.

Pro Tip for Retailers & OEMs:

When sourcing kits for wholesale, ensure beads, threads, and findings are arranged in labeled compartments—this eases assembly-line production and enhances the perceived value of your brand’s kit.

Consumables and Customization Options

While tools form the backbone of your kit, consumable components—like findings, clasps, and wires—complete the jewelry-making experience. Professional OEM suppliers often provide modular options, allowing brands to tailor the content mix to either beginner or advanced buyers.

Common Consumables

| Component | Description | Function |

|---|---|---|

| Beading Wire | Usually nylon-coated stainless steel (e.g., Tiger Tail). | Strong yet flexible for necklaces/bracelets. |

| Elastic Cord or Nylon Thread | Common for beginner kits. | Ideal for stretchy bracelets or small-scale designs. |

| Findings | Includes jump rings, clasps, ear hooks, and crimps. | Used for connecting, closing, or finishing jewelry. |

| Crimp Beads and Covers | Soft metal sleeves crushed onto wire to lock ends. | Ensures security and professional finish. |

| Spacer Beads and Charms | Add decorative or thematic elements. | Provides stylistic diversity and customization potential. |

OEM/ODM Customization Possibilities

Manufacturers offering OEM/ODM services can tailor bead kits with:

- Branding and packaging (e.g., custom printed boxes, logo embossing)

- Material variations (e.g., eco-friendly cords, alloy-free findings)

- Skill-based configurations (Beginner, Intermediate, Professional)

- Specialty inclusions (e.g., gemstone assortments, mini tool sets)

Quality Verification Tips:

- Material Durability: Choose stainless or carbon steel tools with anti-rust coating.

- Precision Check: Ensure pliers align perfectly when closed and cutters produce clean edges.

- OEM Documentation: Request factory QC reports and tool hardness ratings if sourcing in bulk.

Conclusion: Building a Professional Bead Kit that Works for You

The essential tools in a jewelry bead kit—pliers, cutters, threading tools, and layout accessories—form the foundation for any jewelry-making operation. For hobbyists, these empower creativity and consistency. For wholesalers, retailers, or OEM partners, the same tools represent an opportunity to tailor professional kits that align with brand identity and customer needs.

A well-curated bead kit isn’t just a collection of tools—it’s a production system in miniature. Choosing the right components ensures efficiency, professional-quality results, and a smoother workflow from design to distribution.

If you’re a jewelry brand, wholesaler, or OEM partner, investing in customizable, quality-consistent bead kits will not only improve your production standards but also enhance your brand’s value in a competitive marketplace.