Fuse beads—sometimes called iron beads or thermobeads—have transformed from a children’s craft staple into a dynamic design element used by jewelry manufacturers, private label brands, and DIY accessory creators. These tiny cylindrical plastic beads made from low-density polyethylene (LDPE) allow designers to create colorful, pixel-like patterns, then fuse them into durable, customized pieces through heat. In the B2B context, fuse beads have evolved into a flexible production material for sample development, creative jewelry concepts, and educational product lines—all widely sought in bulk from specialized suppliers across China.

Fuse beads are heat-fusible LDPE craft beads used to create design panels, charms, or accessories. When heated under parchment using an iron, they partially melt—bonding together into one cohesive unit. Professional buyers sourcing craft kits or design components can choose from various sizes (mini, midi, maxi), surface finishes (opaque, translucent, glitter), and packaging formats (bulk bags, retail kits, or OEM custom boxes). Fusing quality relies on bead material purity, heat balance, and pegboard precision—critical QC factors for private label sourcing.

From a manufacturing standpoint, fuse beads blend creative functions and reliable physical performance. They fuse under controlled temperature, allowing flexibility in shaping jewelry prototypes or pixel-style pendants. For global distributors and brand owners, understanding bead formulation, melting characteristics, and supplier capacity ensures smoother procurement, especially when buying from Asia-based factories specializing in LDPE molding and OEM craft production.

Table of Contents

ToggleMaterials and Composition: How Fuse Beads Differ from Regular Plastic Beads

Unlike traditional acrylic, ABS, or resin beads used in wholesale jewelry manufacturing, fuse beads are made exclusively from low-density polyethylene (LDPE)—a thermoplastic with unique melting behavior. This allows controlled fusion during heat application, forming a unified design without adhesives.

Material Comparison Table

| Material Type | Common Use in Jewelry Production | Melting Range (°C) | Surface Finish | Fuse Capability | Cost Level (bulk MOQ 10,000 pcs) |

|---|---|---|---|---|---|

| LDPE (Fuse Beads) | Crafts, DIY kits, educational sets | 105–115 | Matte / Semi-gloss | Yes | Low |

| Acrylic | Costume jewelry, charms | 160–180 | Glossy | No | Medium |

| Resin (Epoxy) | Pendants, coated charms | 120–180 | High Gloss | No | High |

| ABS Plastic | Molded accessory parts | 220+ | Glossy / colored | No | Low–Medium |

The LDPE composition gives fuse beads their distinct softness and semi-transparency, allowing easy melting and fusing under moderate household heat—usually applied via an iron. They differ from “regular” jewelry beads because they are functional components in craft design systems rather than stand-alone threaded elements.

Industrial Implication

For wholesale accessory kit suppliers, LDPE fuse beads simplify packaging logistics—lightweight, non-fragile, and available in continual color variations. Factories in Yiwu, Shenzhen, and Ningbo maintain large-scale LDPE extruders, letting fashion jewelry exporters integrate fuse-based design sets into educational collections or private label DIY kits at low MOQ and short lead time.

Designing with Fuse Beads: From Pattern Boards to Jewelry and Keychains

Fuse beads empower designers to prototype intricate, pixel-like accessories at minimal cost. As a manufacturer, I often use them to mock up pendant shapes, charms, and keychains before moving into metal or resin-based mass production.

The Creative Design Workflow

- Sketch a Pattern: Choose grid-based designs—popular motifs include hearts, logos, stars, or initials.

- Arrange Beads on a Pegboard: Place each bead according to the pattern using tweezers or bead pens.

- Apply Heat with an Iron: Cover the design with parchment paper; heat on medium for 10–20 seconds until beads fuse where they touch.

- Cool and Remove: Once cooled, detach from the pegboard. The fused piece can serve as a decorative component or mold basis.

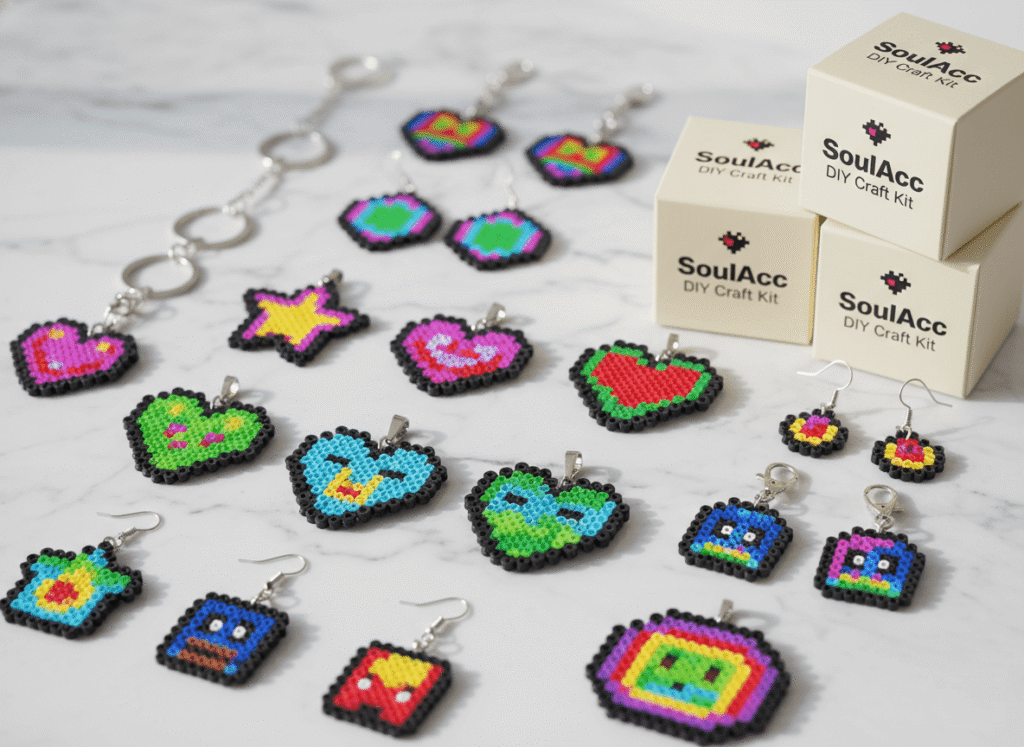

Jewelry Application Ideas

- Charm Pendants: Fuse a compact pattern and glue a jump ring onto drilled holes for necklaces.

- Keychains: Pair fused motifs with metal rings or cords, offering custom designs for event merchandise.

- Earring Panels: Create symmetrical small designs—color blocks or icons—for playful fashion jewelry.

- Brooches or Bag Clips: Fuse thicker layers or double-sided pieces for structural durability.

The fusion technique itself opens creative opportunities. Brands often incorporate fused bead charms into polymer-clay or resin collections as color accents. Bulk OEM suppliers can pre-assemble kits by color palette or theme—making them retail-ready for global distributors.

Understanding the Fusing Process and Heat Application Standards

Proper heating is the most critical step, whether in DIY craft or light industrial assembly. The melting behavior defines both appearance and structural consistency, thus QC protocols matter for large-scale manufacturing.

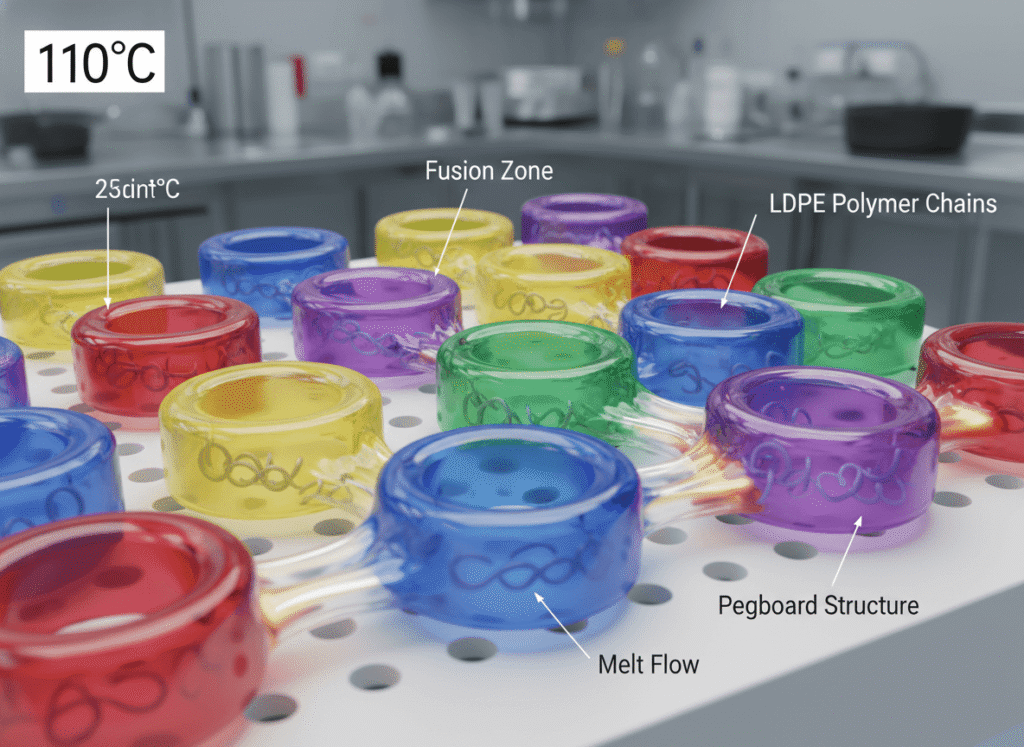

The Thermal Physics Behind Fusing

LDPE beads begin to soften around 105°C, achieving full fusing between 110–115°C. At this range, polymer chains become mobile and intermolecular bonds connect adjacent beads. Excess heat (>125°C) causes deformation or color shifting; insufficient heat leads to weak bonding.

Industrially Recommended Fusing Guidelines

| Parameter | Optimal Benchmark | Effect if Exceeded |

|---|---|---|

| Temperature | 105°C–115°C | Burn marks / discoloration |

| Duration | 10–15 sec per area | Warp or full melt |

| Pressure | Gentle circular motion | Flattened surface |

| Cooling Time | 1–2 min on pegboard | Prevent shrinkage |

Equipment & Safety Control

In factories that integrate fuse bead products into boxed kits, automated heat plates or conveyor fusion systems are used instead of handheld irons. These ensure even heating, minimize operator risk, and improve time efficiency. For small-batch OEM production, handheld iron fusing remains acceptable, controlled by precise operator training.

QC Inspection Criteria

When performing post-fusion inspection, we check:

- Smooth and consistent surface texture

- Partial melting visible only at bead contact points

- Uniform spacing across color boundaries

- Preserved circular holes if design requires flexibility

- No burnt edges or uneven browning

Factories typically perform 5% random inspection per carton, with tolerance levels defined under AQL 1.5 standard for visually observable defects.

Sourcing High-Quality Fuse Beads and DIY Kits from Reliable Chinese Manufacturers

As a long-time OEM/ODM jewelry and craft manufacturer, I source or produce fuse beads through LDPE extrusion and color granule mixing in specialized workshops. In China, several regional clusters dominate the market.

Main Manufacturing Regions

- Yiwu – The hub for small accessories and art craft suppliers, offering broad color assortments and private labeling.

- Shenzhen and Dongguan – Focused on higher-end educational kits and branded packaging.

- Ningbo and Hangzhou – Known for LDPE extrusion quality and consistent supply chain management.

How to Evaluate a Fuse Bead Supplier

When sourcing for wholesale, evaluate suppliers using these benchmarks:

| Evaluation Factor | Why It Matters | Recommended Standard |

|---|---|---|

| Material Purity | Prevents uneven melting | ≥98% LDPE purity |

| Color Uniformity | Ensures consistent visual quality | ±2% color variance |

| Size Accuracy | Enables grid alignment | ±0.05 mm tolerance |

| Packaging | Retail readiness / export compliance | RoHS certified, non-toxic |

| MOQ Flexibility | Facilitates new market testing | ≤5,000 packs per color |

| OEM Service | Branding, packaging design | Available with 3D layout proofs |

OEM/ODM Private Label Opportunities

We can customize:

- Logo-branded boxes and printed instruction manuals

- Themed bead sets (holiday, emoji, alphabet)

- Pegboard shapes in animal or geometric designs

- Fuse bead jewelry starter kits (necklace + charm assembly guides)

OEM/ODM jewelry production using fuse beads provides differentiation for brands targeting the educational craft and lifestyle accessory sectors. These kits often integrate cross-sell opportunities with metal charms, resin pendants, or textile craft components.

Cost Control and MOQ Planning

For bulk orders, cost efficiency depends on:

- Material sourcing agreements (direct polymer purchase)

- Color batching optimization (minimize changeover downtime)

- Automated bagging systems reducing packaging labor

- Consolidated shipping via Ningbo or Yiwu ports for mixed SKUs

Typically, fuse bead sets start from USD 0.12–$0.25 per 100 beads (FOB China) depending on finish type. MOQ: 5,000 packs per design or color assortment.

Additional Practical Knowledge for B2B Buyers

Trend Analysis and Market Outlook

Fuse beads belong to the STEM craft and creative hobby segment, which continues growing due to:

- Rising interest in DIY learning kits

- E-commerce visibility via social media tutorials

- Integration into school art programs and brand merchandise gifting

The global market has experienced steady annual growth (CAGR ~4–5%) in craft and toy accessory exports. Private label brands combining fuse beads with jewelry findings are capturing a new niche—bridging art education and fashion aesthetic.

Environmental and Safety Considerations

Modern LDPE beads often comply with EN71 and ASTM D-4236 safety standards (non-toxic & child-safe). Many factories offer recyclable or biodegradable LDPE options under eco-friendly OEM lines—valuable for sustainability-driven buyers.

Logistics and Supplier Partnership

Best practice is vendor diversification:

- Select one primary factory for extrusion and one for packaging & assembly.

- Conduct factory audits before first order shipment using third-party inspection services (SGS, Bureau Veritas, or Intertek).

- Negotiate long-term supply agreements with fixed color catalog pricing to protect margins during polymer price fluctuations.

Conclusion

Fuse beads represent more than a simple craft material—they embody a flexible, cost-effective design medium suitable for creative jewelry prototyping, educational kits, and decorative accessories. Their unique thermoplastic properties differentiate them from standard beads, making them ideal for small-format production or retail-ready DIY kits.

Key Sourcing Insights:

- Focus on LDPE purity and consistent color quality for optimal fusion results.

- Maintain QC control—monitor heat uniformity and avoid over-fusing.

- Partner with OEM-certified Chinese manufacturers who offer branding and packaging support.

As a professional supplier experienced in both fashion jewelry and craft material sourcing, I always advise B2B buyers to request samples across multiple colors and bead sizes—testing fusion consistency before placing volume orders. If you’re exploring fuse bead kits or custom accessory components, I invite you to contact our factory, review our product catalog, and discuss tailored packaging solutions designed for your target retail segment. Let’s turn creative ideas into scalable, export-ready collections.