Crafting a successful mixed-bead jewelry collection is both an art and a science. For jewelry wholesalers, brand owners, and sourcing managers, mastering the integration of beads from multiple kits enables the development of distinctive styles, efficient inventory utilization, and sustainable product strategies. As a custom jewelry supplier and experienced OEM/ODM manufacturer, I’ve seen how strategic bead mixing transforms ordinary stock into unique, market-ready designs that captivate B2C buyers and strengthen brand differentiation in the competitive fashion jewelry wholesale market.

Mixing beads from different kits enhances product value by combining contrasting materials, sizes, and finishes to achieve greater visual depth and design originality. For B2B jewelry buyers, this technique maximizes inventory efficiency, encourages innovative SKU creation, and optimizes sustainability by reducing leftover stock. The key is identifying compatible bead sizes, harmonizing colors and plating finishes, and maintaining strict quality control across suppliers to ensure consistency in bulk production.

In this guide, I’ll share first-hand insights into material compatibility, color strategy, and QC considerations essential for successful multi-kit jewelry production. We’ll explore how bead selection affects pricing and supply chain logistics—vital knowledge for any stainless steel jewelry manufacturer, private label brand, or wholesale jewelry distributor seeking scalable mixed-bead production capabilities. Let’s dive deeply into the core methods that transform mixed kits into cohesive, export-ready jewelry lines.

Table of Contents

ToggleIdentifying Compatible Bead Sizes and Materials When Combining Multiple Kits

When mixing beads sourced from various regions or suppliers—be it fashion jewelry wholesale China manufacturers or local artisan kit producers—size and material alignment are crucial for both aesthetic and structural integrity.

Understanding Material Compatibility

Each bead material behaves differently under pressure, wear, and plating. Here’s a quick comparison of common bead materials I use in OEM jewelry production:

| Material Type | Core Features | Ideal Application | Notes for Mixing |

|---|---|---|---|

| Glass Beads | Glossy, light-reflective, available in wide color range | Bracelets, earrings, necklaces | Ensure consistent translucency; avoid pairing fragile glass with heavy metals |

| Metal Beads (Brass, Alloy, Stainless Steel) | Durable, luxe appearance | Statement designs, structural elements | Match plating tone; stainless steel resists tarnish best |

| Wood & Acrylic Beads | Lightweight and textured | Bohemian or seasonal collections | Seal for durability, ensure hole sizes align for even threading |

| Gemstone & Crystal Beads | Premium value, radiant colors | Luxe fashion lines | Uniform threading crucial for consistent tension |

Pro Tip: Stainless steel is my go-to for base structures when combining mixed-material beads, thanks to its strength, anti-tarnish capability, and plating compatibility.

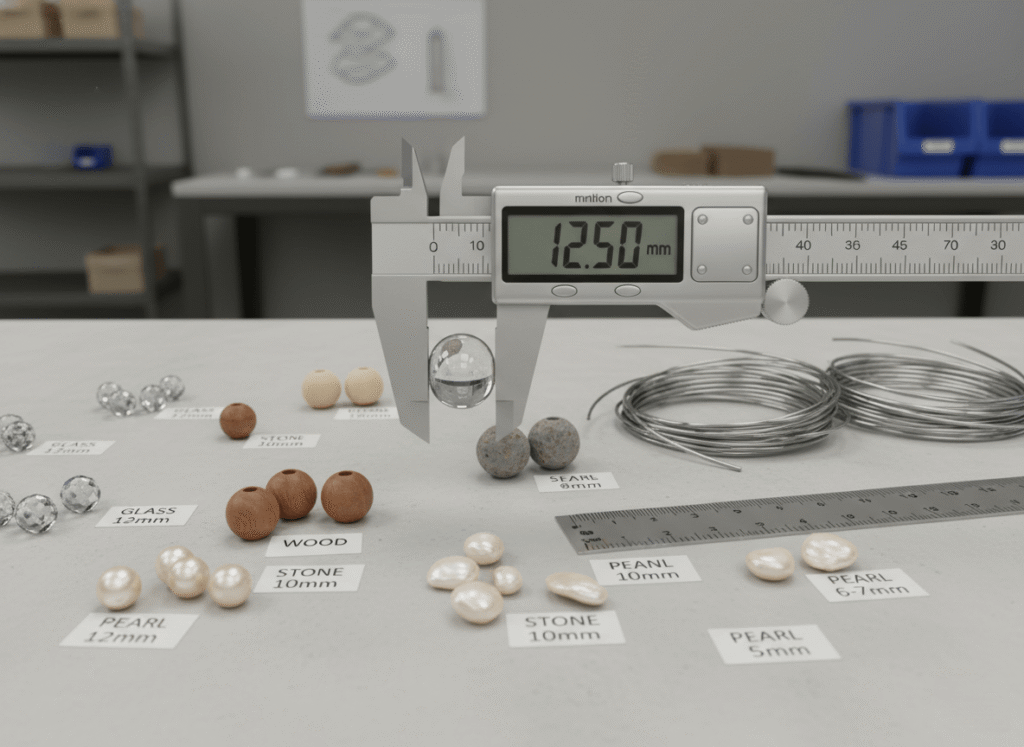

Measuring Compatibility: Hole Size, Wire Gauge & Stringing Material

Confirm that the wire gauge or thread thickness matches bead hole diameter to avoid loose fits. When mixing kits, I standardize stringing wire as follows:

| Bead Hole (mm) | Recommended Wire (inches) | Compatible Bead Types |

|---|---|---|

| 0.5–0.8 | 0.010–0.012 | Pearls, seed beads |

| 0.8–1.2 | 0.014–0.018 | Glass, round acrylic beads |

| 1.5–2.0 | 0.020–0.024 | Gemstones, metal beads |

Maintaining proportional relationships prevents strain during wear and minimizes bulk order returns due to assembly inconsistency.

Tools and Accessories for Efficient Multi-Kit Bead Mixing in DIY or Mass Production

Mixing beads becomes fluid and efficient when the correct tools and accessories are in place—both for individual crafting and scaled B2B sample development.

Essential Tools Overview

- Bead Board or Design Tray: Helps pre-visualize patterns and maintain sequence integrity when mixing kits.

- Digital Calipers: For measuring exact bead diameters—a must when using multiple suppliers.

- Bead Scoops and Tweezers: Streamline sorting, reduce human error, and keep surfaces clean.

- Elastic Cord, Steel Wire, or Nylon Thread: Choose based on product durability requirements.

- Precision Crimping Tool & Jump Ring Pliers: For secure closures and clean finishing edges.

- Labeling System or QR-coded Bags: Useful for tracking mixed-kit combinations in B2B sample databases.

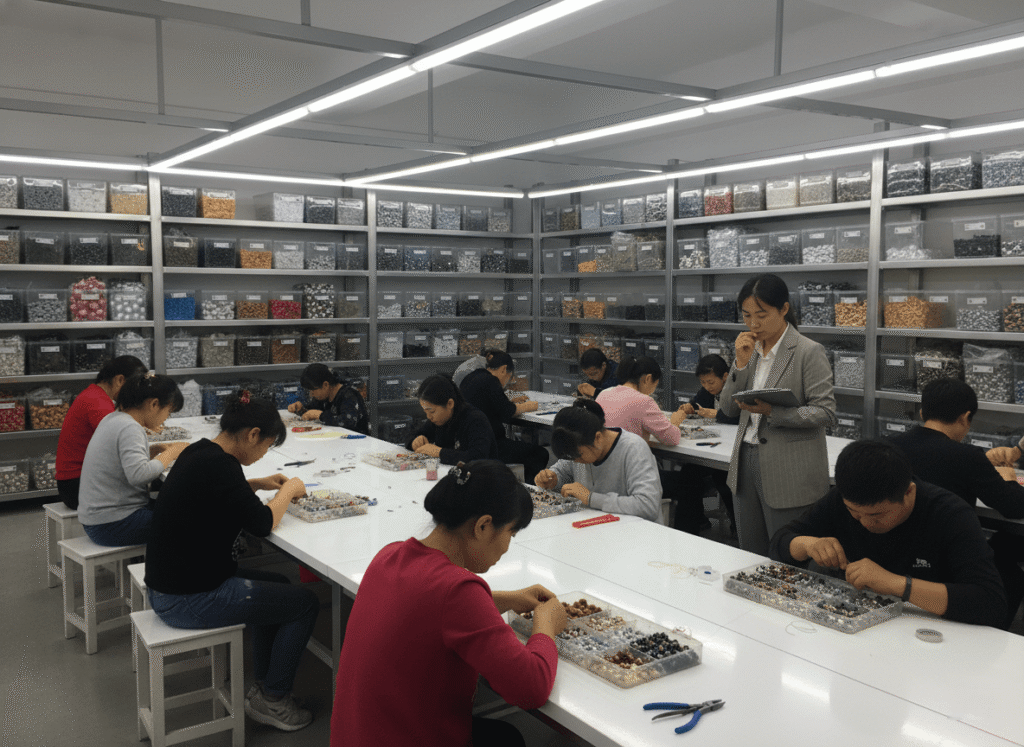

Organizing and Sorting Beads for Mass Mixing

To scale design trials efficiently in a wholesale operation, I group mixed beads by color, size, and plating tone. A standardized sorting protocol ensures repeatability across orders.

Example Workflow in My Factory:

- Step 1: Separate all bead sets into clear bins by material type.

- Step 2: Label each with millimeter size and supplier code for traceability.

- Step 3: Mix secondary colors from different kits to create prototype SKU sets.

- Step 4: Track design outcomes digitally to replicate in OEM/ODM production batches.

OEM/ODM Jewelry Production Considerations

When converting DIY designs to private-label wholesale jewelry, I advise setting MOQ per mixed style (usually 100–300 pcs per colorway). Control costs by reusing existing bead materials across designs—one of the most efficient methods to expand your catalog without increasing raw material imports.

Ensuring Color and Plating Consistency Across Different Manufacturers

One of the most common issues in mixed-kit design for B2B production is the mismatch of color or electroplating tones. Even slight differences in plating thickness or hue can make bulk batches appear inconsistent.

Color Consistency Strategy

I always start by defining a master palette approved by the brand’s visual team. When sourcing beads from multiple kits, compare samples under neutral, daylight-balanced lighting. For bulk production:

- Use Pantone references to standardize colors across suppliers.

- Request pre-plating samples before committing to a full production run.

- Avoid mixing beads from warm-tone plating factories with those specializing in cool-tone finishes unless deliberately designing for contrast.

Plating Quality Comparison

| Plating Type | Common Thickness (μm) | Typical Use Case | Durability Rating |

|---|---|---|---|

| Gold PVD (Stainless Steel) | 0.20–0.25 | Premium pieces, long wear life | ★★★★★ |

| Electroplated Alloy | 0.05–0.10 | Seasonal/trend jewelry | ★★★ |

| Rhodium over Brass | 0.10–0.15 | Anti-tarnish lines, silver tone | ★★★★ |

Tip from Experience: For OEM custom jewelry supplier orders, I often test plating adhesion via a 48-hour salt spray test or abrasion simulation before mass production approval. This ensures assurance in plating quality and uniformity across mixed bead sets.

Harmonizing Textures and Finishes

When working with multiple bead kits:

- Match matte vs. gloss intentionally to balance light reflection.

- Use metallic spacer beads to bridge dissimilar materials.

- Establish a base metal tone hierarchy—usually gold or silver foundation—to guide creative mixing.

This method retains brand coherence even across diverse bead origins.

Quality Control Steps Before Exporting or Wholesaling Custom Beaded Jewelry Creations

Quality control represents the final, decisive stage of mixed-bead jewelry production. For B2B buyers and private-label brands, QC not only ensures design accuracy—it protects market reputation.

Pre-Production QC Checklist

Before launching bulk production, I review:

- Bead alignment consistency across sample patterns.

- Stringing tension—tight enough to maintain structure, flexible enough for comfort.

- Uniformity of plating tone and bead polish.

- Branded tag integration (engraved logo discs or custom packaging if applicable).

In-Process QC (During Production)

Random inspections at 20%, 50%, and 80% completion stages ensure early detection of irregularities. My QC team checks:

- Bead counts per sequence match digital layout.

- No cracks, sharp edges, or misdrilled holes.

- Color deviation under white light does not exceed ±3% tolerance.

Final QC and Export Readiness

| QC Category | Standard | Inspection Process |

|---|---|---|

| Appearance | No visual scratches, cracks, or plating spots | 100% surface scan |

| Color Consistency | Tone deviation <3% | Visual + spectrometer test |

| Assembly Durability | Pull test ≥ 2.5kg for bracelets | Random sampling 10 pcs per lot |

| Packaging | Each item sealed in anti-tarnish pouch | Manual inspection |

Adopting these QC systems ensures that mixed-bead jewelry stands up to both domestic and international standards. I also include detailed inspection reports for each SKU batch, which boosts transparency for global B2B buyers.

Additional Considerations: Supply Chain Optimization & MOQ Strategy

Controlling supply costs for mixed-bead collections requires balancing variety with production efficiency. Here’s how I manage it:

MOQ and Cost Containment Strategy

- Standard MOQ: 100–300 pcs/style — efficient for plating and assembly line setup.

- Shared plating batches for multiple designs save up to 25% on cost per unit.

- Encourage clients to approve modular bead combinations (e.g., same base design, different color versions).

Integrated Supplier Management

Work with 3–5 trusted bead factories rather than dozens of small ones. This ensures consistent quality control and easier troubleshooting. Supplier consolidation also reduces freight costs and QC workload.

Embracing Creativity with Market Alignment

Mixed-bead jewelry aligns perfectly with emerging fashion movements emphasizing sustainability, customization, and small-batch uniqueness. Brands using this strategy can position themselves in the mid- to high-tier fashion jewelry market, offering perceived “handcrafted exclusivity” while benefiting from scalable OEM manufacturing.

From market observation:

- The 2024 buyer trend leans toward eco-conscious mixed textures (wood and recycled glass combinations).

- Consumers respond strongly to storytelling-based collections, particularly those highlighting cultural inspiration.

Consider developing thematic lines such as:

- “Urban Mosaic” – metallic and acrylic blends.

- “Nature Harmony” – wood, shell, and glass mixes.

- “Era Fusion” – vintage brass with modern resin geometries.

These themes elevate mixed-kit jewelry from DIY-level crafting to full-fledged brand collections fit for export retail.

Conclusion: Turning Mixed Bead Kits into Scalable Jewelry Collections

Mixing beads from different kits is more than a design experiment—it’s a smart B2B sourcing and product development strategy. By mastering compatibility across sizes and materials, maintaining consistent plating quality, and enforcing strict QC workflows, brand owners and wholesalers can confidently produce on-trend mixed-bead collections with reliable repeatability.

Key Takeaways for Jewelry Sourcing Professionals:

- Match hole size, material hardness, and plating tone before commencing mixed-kit designs.

- Use appropriate tools and digital documentation for repeatable patterns.

- Standardize QC testing in all stages—from sample to final inspection—to secure consistency in exports.

- Collaborate with experienced OEM/ODM jewelry manufacturers to streamline production and ensure reliable results.

Ready to elevate your next jewelry collection?

👉 Request samples, explore custom bead combinations, or contact our production team to develop mixed-bead designs tailored for your market.