In the B2B fashion jewelry market, details define quality. From statement necklaces to intricate bracelets, every component contributes to both perceived value and functional durability. Among these components, metal spacer beads play an unmistakable role in shaping jewelry aesthetics and craftsmanship. As a jewelry manufacturer or supplier, I’ve seen firsthand how small design decisions—like choosing the right spacer bead material—can transform an ordinary concept into a commercially successful piece. For wholesalers, brand owners, and private label buyers, understanding how spacer beads influence design, structure, and longevity is essential for building a profitable, sustainable product line.

Metal spacer beads are not just fillers—they are design enhancers, structure stabilizers, and durability protectors. When sourced strategically from a reliable wholesale jewelry manufacturer, they can:

- Improve balance and symmetry in multi-bead designs

- Add sophisticated metallic texture and shine

- Prevent wear between gemstones and softer materials

- Increase the overall perceived value of your jewelry collections

From material choice to plating techniques and cost optimization, selecting the right spacer beads is about more than aesthetics—it’s about maintaining consistency across large-scale production. Let’s explore how these small yet significant components influence not only creativity but also long-term quality control, sourcing efficiency, and your product’s retail success.

Table of Contents

ToggleHow Do Metal Spacer Beads Enhance Jewelry Designs?

As a long-time fashion jewelry manufacturer, I often describe metal spacer beads as the “architectural framework” of jewelry design. They shape the structure, dictate balance, and subtly define luxury through symmetry and finish.

Visual Enhancement & Pattern Control

Metal spacer beads provide rhythmic separation that breaks visual monotony. Whether working with gemstone strands, faceted glass, or resin beads, spacers bring order and movement into repetitive designs. A simple alternation—round beads + spacer + gemstone—can elevate a mid-tier collection into a sophisticated retail product.

Key advantages:

- Create focal balance by guiding visual flow toward key design elements.

- Provide metallic contrast to accent gemstone colors.

- Support refined symmetry in multi-strand builds and layered compositions.

Functional Protection & Longevity

Spacer beads preserve surface integrity by reducing direct contact between softer materials like pearls, turquoise, or crystal beads. This functional buffer layer prevents abrasion, discoloration, and cracking, ensuring jewelry remains pristine through frequent wear.

Industrial implication:

B2B buyers sourcing premium handcrafted items rely on spacer beads to extend product life and reduce after-sales issues related to wear damage—an important consideration for brands seeking low return rates and high customer trust.

Material Consistency & Coordination

Coordinating the plating tone of spacers with other metal components—like clasps or settings—creates cohesiveness. This is crucial for private label jewelry production, where visual consistency defines brand identity. Gold-plated spacers paired with gold findings yield harmony and enhance visual continuity across the full product line.

What Should I Consider When Sourcing Metal Spacer Beads for My Jewelry Production?

Sourcing metal spacer beads is not just about selecting styles; it’s an integrated process involving quality, cost, and manufacturability assessments. Whether you purchase from a fashion jewelry wholesale supplier in China or a domestic partner, every sourcing stage must align with brand positioning and target retail pricing.

OEM, ODM, and Private Label Sourcing Strategies

| Sourcing Model | Description | Advantages |

|---|---|---|

| OEM (Original Equipment Manufacturer) | Buyer provides full design and specifications. | Total control over customization, perfect for established brands. |

| ODM (Original Design Manufacturer) | Supplier offers pre-developed designs for rebranding. | Faster lead time, lower R&D cost. |

| Private Label Production | Combines partial OEM and ODM approaches. | Balanced flexibility, ideal for fast-evolving jewelry lines. |

In my experience, combining OEM precision with ODM flexibility ensures optimal product diversity without overcomplicating MOQs or inventory cycles.

QC Standards and Inspection Criteria

Quality control is crucial in scaling spacer bead orders. Common QC parameters include:

- Plating adhesion test: Assess resistance to tarnish and wear.

- Dimensional accuracy: Ensure hole diameter consistency for smooth threading.

- Weight tolerance: Maintain uniformity across production batches.

- Finish uniformity: Check for scratches, dents, or uneven coloration.

For bulk sourcing, many reliable suppliers conduct a 100% plating consistency check, especially for PVD-coated stainless steel and IP-plated alloy spacers.

MOQ Planning and Cost Optimization

Spacer beads are generally low-cost—and high in order volume. To optimize production:

- Negotiate with suppliers to combine multiple spacer styles under one MOQ.

- Choose modular bead molds to share base material cost across designs.

- Consolidate shipments to reduce freight per-unit costs.

In fashion jewelry wholesale, small savings in per-unit material cost translate into substantial profit margins across bulk production.

How Can I Choose the Right Spacer Bead Material for My Custom Jewelry Line?

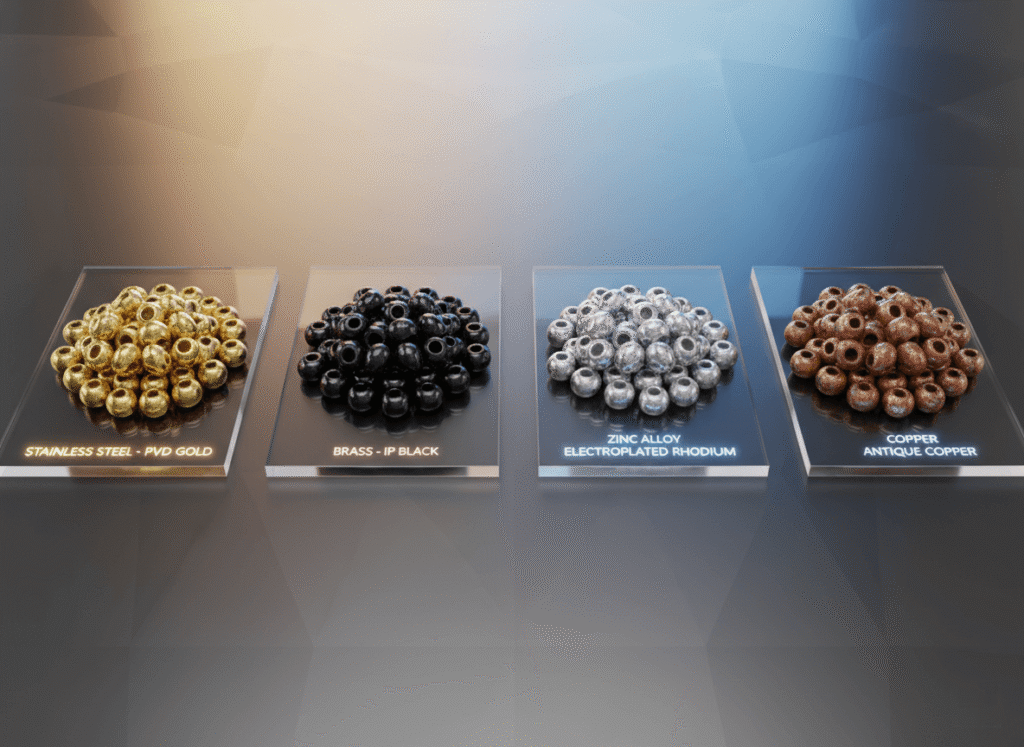

Material selection defines both aesthetic appeal and long-term durability. Each metal option—stainless steel, brass, or alloy—serves distinct branding, cost, and craftsmanship purposes.

Material Comparison Table

| Material | Features | Strength | Plating Compatibility | Market Use |

|---|---|---|---|---|

| Stainless Steel | Corrosion-resistant, hypoallergenic, lead & nickel free. | Very High | Excellent (IP/PVD) | Mid-to-high-end fashion jewelry |

| Brass | Soft, easy to shape, good for detailed spacer designs. | Medium | Excellent (Rhodium, Gold, Silver) | Trendy & artisan collections |

| Zinc Alloy | Affordable, lightweight, high design flexibility. | Low | Good (electroplated) | Mass-market & costume jewelry |

| Copper | Natural shine, antimicrobial, vintage appeal. | Medium | Good | Boho & handmade designs |

As a stainless steel jewelry manufacturer, I often recommend stainless steel spacers for durability-critical products such as men’s jewelry or minimalist modern pieces. For intricate artistic lines, brass and copper spacers offer exceptional versatility for custom textures and finishes.

Plating Quality and Color Retention

Modern plating technologies have refined how spacer beads retain their brilliance. The industry standard now favors:

- IP (Ion Plating) for scratch and tarnish resistance.

- PVD (Physical Vapor Deposition) for premium luster durability.

- Electroplating for varieties needing broader color range and cost control.

Plating Method Comparison

| Plating Method | Durability | Color Options | Ideal For |

|---|---|---|---|

| PVD Coating | ★★★★★ | Limited (Gold, Silver, Black) | Premium stainless steel jewelry |

| IP Plating | ★★★★☆ | Moderate | Daily wear collections |

| Electroplating | ★★★☆☆ | Broad (Rose, Rhodium, Antique) | Mass-market fashion jewelry |

Choosing the correct plating depends on your target demographic and retail price band. For example:

- Mid-tier fashion brands prefer IP-plated brass for affordability and good color stability.

- High-end retailers demand PVD stainless steel components to minimize after-sales maintenance.

How Do Metal Spacer Beads Affect the Durability and Aesthetic of My Finished Jewelry?

The right spacer bead doesn’t just beautify—it fortifies. Designers who fully grasp the interplay between bead materials and stringing mediums can enhance both appearance and functionality.

Structural Durability & Wear Resistance

Spacer beads minimize frictional wear, especially for bracelets or necklaces with constant movement. They distribute tension evenly and prevent thread breakage at bead junctions. Stainless steel spacers, with their superior hardness, are best for high-stress joints such as toggles or clasp-end beads.

Aesthetic Versatility Across Collections

Color-matched spacers contribute to design harmony across multi-piece lines. For example:

- Silver-plated spacers match cool-toned crystal beads.

- Antique brass spacers complement earthy or boho designs.

- Matte black stainless spacers add sleek modern appeal to men’s accessories.

This consistency not only aids aesthetic refinement but strengthens brand visual identity—a key factor for multi-channel retail brands aiming for cohesive online and in-store presentation.

Tactile and Comfort Considerations

Ergonomic comfort is often overlooked in wholesale design development. The smooth finish of polished spacers reduces skin irritation, an important advantage when selling hypoallergenic collections or premium stainless steel jewelry to Western markets sensitive to nickel or lead exposure.

Pro Tip: Always ensure plating used on spacer beads passes EU REACH and CPSIA standards if exporting to North America or Europe.

Where Can I Find a Reliable Wholesale Supplier for Metal Spacer Beads in China?

Finding a trustworthy supplier is foundational to long-term business success. China remains the leading source for fashion jewelry wholesale production, offering unmatched scalability, OEM/ODM experience, and cost efficiency.

Key Supplier Selection Criteria

| Evaluation Aspect | What to Look For | Why It Matters |

|---|---|---|

| Experience | 10+ years in metal jewelry manufacturing | Proven expertise ensures fewer production errors |

| Material Certification | Nickel-free, lead-free metals | Compliance protects brand integrity and consumer safety |

| Plating Facility | In-house or certified subcontractor | Guarantees plating uniformity across orders |

| MOQ Flexibility | Low MOQs for sampling, scalable bulk terms | Ideal for growing private label operations |

| Communication & Support | Dedicated English-speaking sales support | Speeds up project timelines & customization |

Recommended Sourcing Hubs

- Guangdong (Dongguan, Guangzhou): Stainless steel and brass spacer production centers with strong OEM/ODM expertise.

- Yiwu, Zhejiang: Cost-effective options for zinc alloy and mixed-metal spacer beads.

- Shenzhen: Premium plating houses specializing in IP/PVD coating for stainless steel jewelry lines.

Before committing to large MOQs, request:

- Material composition reports

- Plating adhesion test results

- Finish samples for inspection

This ensures alignment between quality expectations and supplier capability.

Additional Insight: Market Trend Analysis for Spacer Beads in Global Jewelry Production

Market trends show increased adoption of stainless steel spacer beads for minimalist and sustainable jewelry concepts. As consumers demand eco-conscious materials, steel’s recyclability makes it a favored alternative to traditional alloy bases.

Emerging styles include:

- Micro spacer chains: Integrating spacers directly into link patterns.

- Textured finishes: Hammered and frosted surfaces gaining popularity in boho and artisan collections.

- Dual-tone plating: Bi-color spacers enhancing contrast in mixed-metal jewelry lines.

Global Market Behavior

| Region | Demand Trend | Popular Materials | Style Notes |

|---|---|---|---|

| North America | Stable growth in stainless steel category | IP/PVD coated steel | Minimalist & unisex |

| Europe | High sustainability focus | Recycled brass, eco-steel | Vintage & organic finishes |

| Middle East | Strong demand for ornate designs | Gold-plated alloy | Luxurious & textured |

| Asia-Pacific | Fastest-growing segment | Brass, zinc alloy | Bold color and affordability |

For B2B buyers, aligning spacer bead inventories with these regional preferences enables faster adaptation to shifting retail trends.

Conclusion

Metal spacer beads may be small, but their impact on design harmony, product durability, and perceived value is immense. From OEM production lines to wholesale jewelry supply chains, these tiny components determine craftsmanship integrity and profitability. The key is understanding their material behavior, plating quality, and sourcing nuances.

Key Takeaways for Buyers:

- Prioritize stainless steel or brass spacers for longevity and quality perception.

- Verify plating standards (PVD/IP) for color stability and durability.

- Develop partnerships with certified Chinese suppliers offering MOQ flexibility.

- Utilize spacers not just as gaps—but as design signatures that elevate your collection.

Ready to Upgrade Your Jewelry Line?

Partner with a certified custom jewelry supplier experienced in OEM/ODM production for metal spacer beads and components.

Request samples, explore plating finishes, and experience how precision parts turn your designs into market-ready masterpieces.