Jewelry bead kits have become an essential starting point for both individual creators and B2B buyers exploring do-it-yourself jewelry concepts. For wholesalers, brand developers, and retailers, bead kits provide a clear entry into the DIY jewelry market, which continues to expand across global consumer segments. Whether you’re an established fashion jewelry manufacturer, a private label buyer, or a custom jewelry supplier, understanding how bead kits empower creativity and streamline sourcing is crucial for building a differentiated product offering.

Jewelry bead kits simplify jewelry making by offering pre-selected beads, findings, wires, and tools—all coordinated and quality-controlled. They remove the complexity of material sourcing, provide cost-effective starter packages for learning and production, and enable creative customization at scale. For B2B buyers, bead kits represent ready-to-sell or ready-to-assemble solutions that minimize development time and enhance product diversity across markets.

As a jewelry manufacturer specializing in both OEM/ODM jewelry production and wholesale kit assembly, I’ve seen how these kits bridge the gap between creativity and supply chain practicality. From sourcing stainless steel components to curating plated findings with long-lasting durability, bead kits are not just educational tools—they’re scalable products driving jewelry brand innovation worldwide. Let’s explore how they help you start making your own jewelry while opening new market opportunities in the B2B jewelry space.

Table of Contents

ToggleWhat Materials Should I Look for When Choosing a DIY Jewelry Bead Kit for Beginners

The heart of any jewelry bead kit lies in its material selection. For both end-users and wholesale buyers, choosing kits with premium, durable components ensures satisfaction and resale potential.

Essential Materials in a Quality Bead Kit

When I assemble bead kits for global clients, I focus on materials that balance aesthetic appeal, durability, and cost efficiency. A well-structured beginner bead kit should include:

- Beads: Glass, acrylic, natural stone, stainless steel, or plated brass beads in assorted colors and finishes.

- Wires & Strings: Elastic cords for bracelets, nylon threads for necklaces, or stainless steel wire for heavier designs.

- Findings: Clasps, jump rings, crimp beads, and ear hooks—all matching in finish to maintain design consistency.

- Tools (optional): Pliers, tweezers, and cutters for immediate usability.

- Instruction Guide: Clear, beginner-friendly tutorials that can be understood across languages—especially important for international buyers.

Material Comparison for B2B Buyers

| Material Type | Durability | Aesthetic Quality | Best Suited For |

|---|---|---|---|

| Stainless Steel | Excellent | High-polish, modern look | Long-lasting jewelry, premium kits |

| Brass | Good | Warm golden tone | Fashion jewelry and mid-tier kits |

| Alloy | Moderate | Versatile plating options | Budget-friendly starter kits |

| Acrylic | Low | Vibrant colors, lightweight | Kids’ kits or low-cost retail |

| Glass | Good | Elegant shine, various finishes | Beaded bracelets and necklaces |

From experience, stainless steel jewelry components outperform alloy and brass for long-term durability. However, alloy-based kits can be cost-effective for large-scale retail programs where entry-level pricing drives volume.

Key Considerations in Material Selection

- Plating Quality: Ensure supplier uses advanced electroplating with protective coatings to avoid tarnishing.

- Corrosion Resistance: Stainless steel and vacuum-plated brass resist discoloration from sweat or cosmetics, ideal for end-consumer use.

- Color Consistency: When scaling production across thousands of kits, uniform bead hues and coatings matter for brand reliability.

- Sourcing Transparency: Work with verified factories offering detailed material specifications and plating test reports.

By understanding these material aspects, a buyer can make informed decisions, whether purchasing finished kits or sourcing components for private label assembly.

How Can I Ensure the Beads and Findings in My Kit Are High Quality and Durable

Quality assurance becomes the differentiator between low-margin bead kits and premium jewelry-making collections. As a manufacturer, I integrate multi-step QC protocols that ensure consistency in every shipment.

Supplier and Material Verification

Before mass production begins, I always request sample evaluations and conduct physical inspections on bead coatings, hole alignment, and stringing durability. High-quality bead kits require:

- Certifications & Reports: Material safety test (nickel-free, lead-free, cadmium-free).

- Surface Finish Test: Ensuring plating thickness meets 0.1–0.3 microns for longevity.

- Weight & Size Tolerance Checks: ±0.2mm accuracy on bead dimensions for consistent threading.

Factory-Level Quality Control Process

| QC Stage | Inspection Type | Key Criteria | Sampling Plan |

|---|---|---|---|

| Incoming Material | Visual & chemical testing | Purity, plating adhesion, bead hole accuracy | AQL 1.5 |

| In-Process | Random inspection | Thread alignment, packing integrity | Hourly monitoring |

| Final Inspection | 100% piece check (bulk kits) | Completeness, surface finish | Full audit |

Tips for Ensuring Kit Durability

- Partner with OEM/ODM jewelry manufacturers who provide batch plating documentation and salt spray test results.

- Request pre-shipment samples to assess bead uniformity and colorfastness under UV light.

- Prioritize suppliers offering post-sale QC guarantees—a rare but valuable practice in the bead kit segment.

High-quality bead kits retain luster, resist tarnish, and allow multiple design uses. When selecting your B2B supplier, don’t settle for decorative variety alone—opt for verified craftsmanship and standardized QC benchmarks.

What Steps Should I Follow to Design and Assemble My Own Jewelry Pieces from a Kit

If you’re new to DIY jewelry, or managing a brand that wants to launch creative workshops or beginner jewelry lines, mastering assembly workflow is key. Over time, I’ve developed a proven process that guides both hobbyists and OEM clients from idea to prototype.

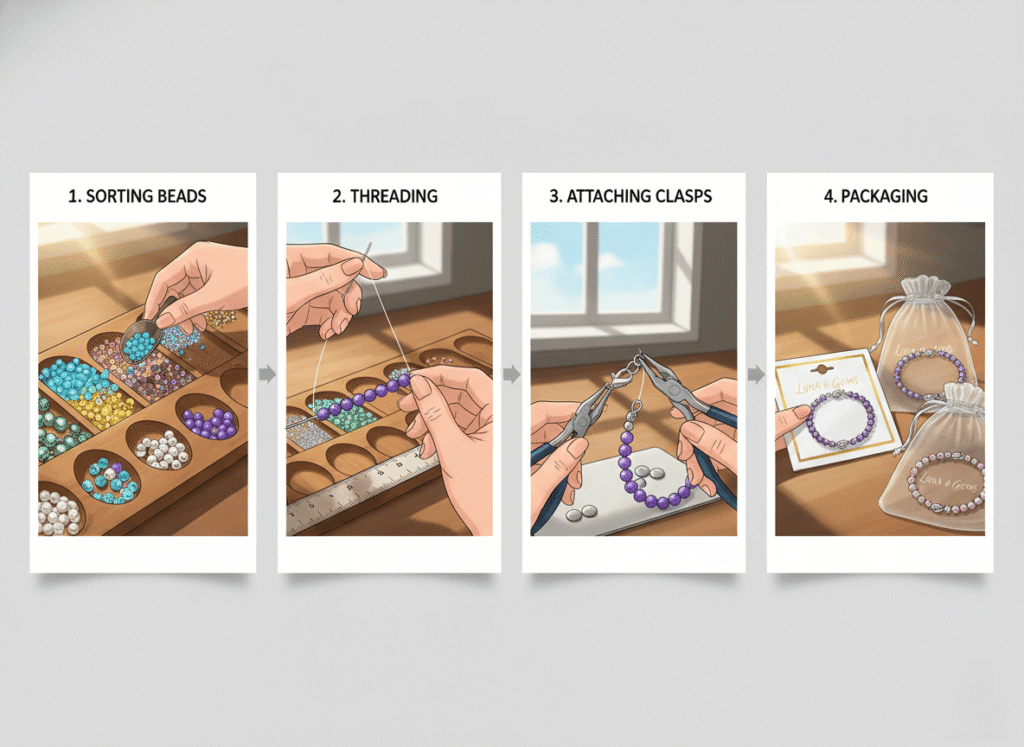

Step-by-Step Assembly Workflow

- Unbox & Organize: Sort beads by color, size, and material. Keep findings in separate trays.

- Design Layout: Use a bead board or sketch inspirational patterns before threading.

- Prepare Stringing Material: Cut wire or elastic to desired length, adding an extra inch for knots or crimps.

- Thread Beads: Maintain symmetry for balanced design; mix textures for visual depth.

- Attach Findings: Use jump rings or clasps with pliers; secure crimp beads firmly.

- Fine Tune Design: Test the wearability and adjust tension or bead spacing.

- Finalize Packaging: Place finished jewelry in sealed pouches or branded display cards for retail readiness.

Practical Sourcing Strategies for B2B Clients

For wholesalers or brands establishing custom bead kit programs:

- Private Label Production (OEM): Work with suppliers offering branding options—logo on tools, box design, and customized bead color themes.

- ODM Program: Utilize design prototypes provided by the factory and modify bead arrangements to fit your target audience.

- Batch Assembly Outsourcing: Hire assembly teams for mass production; maintain QC through third-party inspection.

Cost Control & MOQ Planning

Managing MOQ and cost is fundamental to profitable bead kit sourcing. Below is a general illustration:

| Production Model | MOQ | Lead Time | Suitable For |

|---|---|---|---|

| OEM Custom Kit | 1,000 sets | 20–30 days | Brand owners, online retailers |

| ODM Ready Design | 500 sets | 10–15 days | Wholesalers, distributors |

| White Label Bulk | 100 sets | 7–10 days | Local craft shops, small brands |

Successful kit sourcing hinges on balancing customization with efficient batch output. Avoid overly low MOQs unless you’re validating market response—scaling later with proven designs ensures stronger margins.

Where Can I Find Reliable B2B Suppliers Offering Wholesale or Custom Bead Kits for Jewelry Making

Finding trusted suppliers can transform your product portfolio from average to high-value. Having worked with factories across China, Thailand, and India, I can share proven approaches for identifying, evaluating, and partnering with reliable B2B bead kit manufacturers.

Recommended Supplier Sourcing Channels

- Verified B2B Platforms: Alibaba, Made-in-China, Global Sources—look for suppliers with jewelry kit export experience.

- Specialized OEM Factories: Stainless steel jewelry manufacturers expanding into bead kit assembly.

- Local Trade Fairs: Canton Fair (China) and Hong Kong Jewellery & Gem Fair showcase professional kit suppliers annually.

- Private Label Partnerships: Companies offering design protection and branding confidentiality.

Supplier Evaluation Checklist

| Evaluation Criteria | What to Check | Notes |

|---|---|---|

| Experience | Years in jewelry production | Prefer >5 years in bead kit OEM |

| Quality Assurance | QC certifications, plating test reports | Must provide sample inspection data |

| Customization Ability | Custom logo, packaging design | Essential for brand differentiation |

| Production Scalability | Monthly capacity (10k sets + recommended) | Ensures ability to handle peak orders |

| Communication & Response | Clarity, English fluency, response speed | Impacts turnaround efficiency |

Pricing & Logistics Insight

- Bulk Discounts: Usually offered for orders above 5,000 kits per SKU.

- Global Shipping: Use freight forwarders experienced in jewelry commodities to minimize customs delays.

- Packaging Options: Eco-friendly boxes, zip bags, or gift-style containers—choose based on market positioning.

- Lead Times: Efficient manufacturers promise 10–20 business days after sample approval.

The Sustainability Angle

With growing global concern over environmental footprint, many buyers now request eco-friendly bead kits featuring recycled glass, sustainable wood beads, and biodegradable packaging. Aligning with these trends strengthens your brand legitimacy in western markets.

Trend Insights: Market Behavior in DIY Jewelry Kits

Across multiple regions, DIY bead kits are shifting from simple hobby items to educational and lifestyle products. Here are current observations:

- Rising Demand in North America: Driven by social media crafts and healing crystal trends.

- Increased Corporate Orders: Brands using bead kits for creative workshops and promotional giveaways.

- Private Label Growth: Major brands launching own bead-making series under boutique sub-labels.

- Customization Culture: Consumers seeking personalized bead combinations—inspiring modular kit structures.

For distributors, tapping into this trend offers an ideal mix of creative appeal + repeat purchasing potential, especially when integrating high-quality materials and accessible pricing.

Conclusion: Start Smart with Bead Kits

Jewelry bead kits aren’t just a doorway for beginners—they’re a scalable product line linking creativity with production reliability. When you choose bead kits built with stainless steel findings, coordinated beads, and verified plating quality, you position your brand for long-term success.

Key Takeaways for B2B Buyers:

- Always validate material quality and QC reports before committing to bulk orders.

- Explore OEM/ODM partnerships for private label bead kits adaptable to your brand.

- Balance cost efficiency with durability—stainless steel kits build lasting customer trust.

- Follow global DIY jewelry market trends to anticipate consumer preferences.

If you’re a wholesale jewelry buyer, distributor, or private label developer, consider requesting samples or exploring our latest catalog of custom bead kits tailored for every skill level and market niche. Let’s collaborate to turn creative beginnings into sustainable jewelry business growth.