As a long-time jewelry and accessory manufacturer working with both classic bead materials and innovative crafting mediums, I often encounter questions from sourcing managers and global buyers about fuse beads—how they differ from traditional jewelry beads and whether they fit within certain product categories. Fuse beads, originally designed for craft and pixel-style art, are gaining interest among private label buyers looking for educational, hobbyist, and DIY-oriented product extensions beyond standard jewelry components. Understanding their material composition, processing method, and aesthetic applications is essential for informed decision-making in B2B wholesale sourcing.

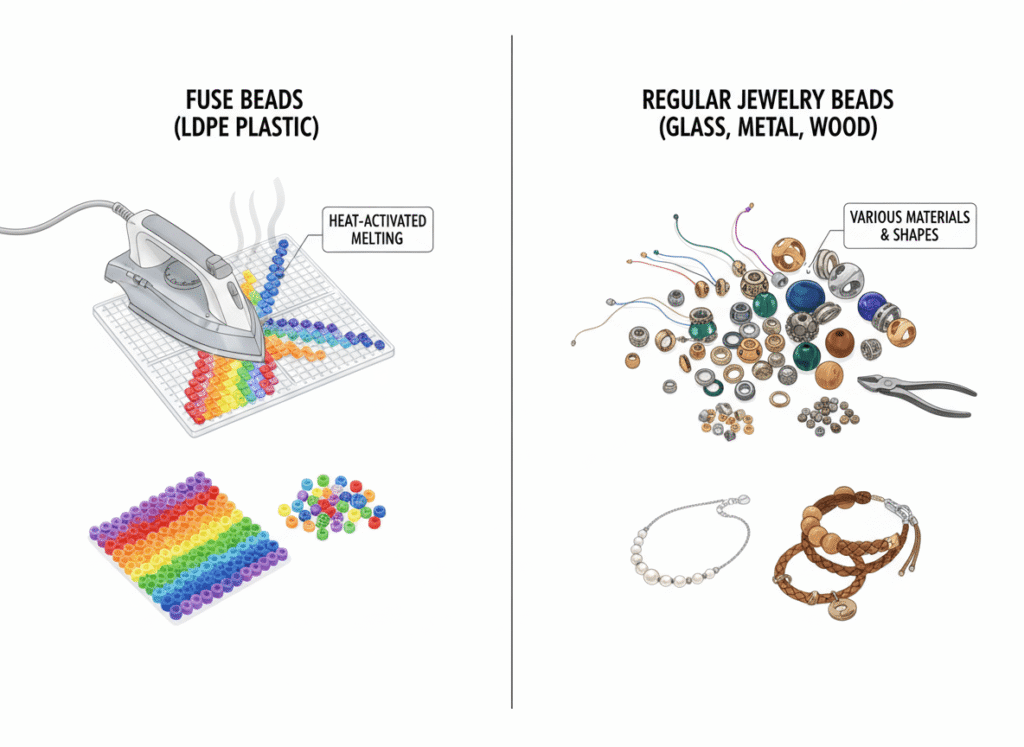

Featured Summary: Fuse beads are made from low-melting thermoplastic materials like LDPE, engineered to be heat-fused into solid, flat designs, while regular beads (glass, metal, wood, or polymer clay) are intended for threading, beading, or embellishment. Fuse beads suit DIY and children’s crafts but have limited durability for wearable jewelry, requiring careful sourcing, color consistency checks, and supplier QC assurance for large-volume imports.

For manufacturers and suppliers in the fashion jewelry wholesale China ecosystem, fuse beads present unique production and logistics conditions. Their cost per kilogram, color standardization, and packaging methods differ markedly from conventional jewelry beads. As a custom jewelry supplier, I’ll guide you through comparing fuse beads with standard beads, assessing material durability, evaluating suitability for your product line, and ensuring top-tier OEM/ODM production quality when sourcing in bulk from Chinese manufacturers.

Table of Contents

ToggleFuse Beads vs. Regular Beads: Design and Functionality

The distinction between fuse beads and conventional jewelry beads starts with their original intent. Fuse beads are designed for melting and fusing together under controlled heat, while traditional beads are created to remain discrete and mechanically joined.

How Fuse Beads Work

Fuse beads are small, uniform, hollow cylinders made from low-density polyethylene (LDPE) or similar thermoplastic materials. They are arranged on pegboards to form pixel-style designs and then fused using heat (usually an iron).

Once fused, these beads bond into a single, flat, cohesive design. The result is rigid and self-supporting—perfect for display pieces or keychain accessories but not flexible enough for wearables.

Functionality of Regular Beads

Regular beads, on the other hand, maintain their distinct shapes and finishes, strung on thread, wire, or elastic to form necklaces, bracelets, or embroidery embellishments. Common bead materials include:

- Glass: Lustrous and elegant but fragile

- Brass/Metal: Durable, used for high-end jewelry

- Wood or Clay: Organic texture and artisanal aesthetics

- Acrylic or Resin: Affordable and versatile for fashion jewelry OEM programs

Fuse beads simplify crafting for beginners, while traditional beads offer broader creative flexibility and structural stability for designers.

Materials and Durability Comparison

Understanding the material composition helps determine production capability and market suitability.

Typical Materials Used

| Bead Type | Material | Manufacturing Process | Melting Point | Durability | Primary Use |

|---|---|---|---|---|---|

| Fuse Beads | LDPE / EVA Plastic | Injection molding | ~110°C | Medium (softens under heat) | Craft & DIY art |

| Regular Beads | Glass, Metal, Clay, Resin | Casting, Pressing, Finishing | Varies (High) | High | Jewelry & embellishments |

Durability Insights

Fuse beads soften under heat and can deform under prolonged exposure to high temperatures, which limits their use in wearable jewelry. In contrast, jewelry beads—whether metal or glass—offer long-term stability and resistance to wear and friction.

From experience, global buyers sourcing DIY products should verify each fuse bead batch’s heat resistance tolerance and plastic grade during OEM/ODM sample production.

Visual & Structural Characteristics

Fuse bead art is defined by shape uniformity and pixel precision. Regular bead designs thrive on texture, 3D layering, and material contrasts—a quality particularly important for fashion jewelry wholesalers catering to boutique and mid-market brands.

Evaluating Suitability for DIY and Craft Jewelry Production

Fuse beads can enrich a product portfolio targeted at hobbyists, educational retailers, and family craft stores—but they occupy a different niche than luxury or daily wearable jewelry.

Key Suitability Considerations:

- Target Market Alignment: Fuse bead kits attract craft enthusiasts and educational distributors rather than traditional jewelry retailers.

- Product Type Integration: Excellent for keychains, coasters, ornaments, and decor—less ideal for flexible jewelry pieces.

- Processing Feasibility: Can be assembled as semi-finished goods (pegboard + beads + iron paper) in packaging units for retail.

- Minimum Order Quantity (MOQ) Planning: Standard MOQ from Chinese fuse bead suppliers ranges from 5,000–10,000 sets.

- Customization Capability: Limited compared to traditional bead materials—color mixing and pixel shapes are fixed.

As a manufacturer, I advise buyers to evaluate whether fuse bead products complement or extend their existing jewelry catalog into DIY or educational segments.

OEM/ODM Production Strategy

For large-scale private label orders:

- Include branded pegboards and design booklets.

- Request color chart confirmation before approval.

- Define polybag or boxed packaging standards.

- Validate heat fusing performance through pilot testing samples.

Sourcing Fuse Beads in Bulk from Chinese Manufacturers

Sourcing fuse beads involves a different set of logistics and inspection routines compared to normal wholesale jewelry operations.

Key Bulk Sourcing Factors

- Material Origin: Verify LDPE source—top-tier manufacturers use non-toxic, odor-free, eco-grade plastic.

- Color Precision: Check against Pantone visual tolerances to ensure consistency across multiple batches.

- Size Accuracy: Typical fuse bead diameter = 5mm ±0.1mm; uniform sizing is crucial for pegboard compatibility.

- Packaging Efficiency: Bulk cartons often contain 100,000–500,000 beads; factor in weight and carton dimensions for freight optimization.

- Heat Tolerance QC: Conduct sample melting tests to ensure even bonding—important for craft quality assurance.

Supplier Evaluation Table

| Evaluation Criteria | Excellent Supplier | Average Supplier | Poor Supplier |

|---|---|---|---|

| Material grade | LDPE food-safe, odorless | Standard plastic | Recycled/off-grade plastic |

| Color consistency | ≤ ±3 Pantone variance | ±5 Pantone variance | Visible mismatch |

| Bead uniformity | Highly consistent | Minor deviation | Uneven sizes |

| Shipment QC | Batch-inspected | Random sample | No inspection |

| After-sales service | 24h response & recheck | Limited service | No aftercare support |

Top-tier fashion jewelry wholesale China suppliers already manage multiple color injection units, allowing custom color production for OEM accounts.

Supply Chain Cost Control

Fuse beads are light but high in unit volume. Freight considerations differ from metal beads:

- Sea freight is cost-effective for 50,000+ set orders.

- Air freight works for rush seasonal samples.

- Negotiate combined shipments if sourcing multiple craft components (pegboards, packaging inserts).

Ensuring Color and Size Consistency for Export or Wholesale

Consistency across tens of thousands of units determines whether your product line passes importer inspection standards.

Quality Control (QC) Practices

- Color Sorting: Use optical color recognition scanners at the manufacturing stage.

- Batch Sampling: Inspect 10% random pieces per lot to detect variation in hue or molding precision.

- Heat Test: Melt-test spot samples at target temperature (~110°C) and measure fusion performance.

- Size Verification: Employ micrometer or 3D measurement for precise diameter consistency.

QC Standards Checkpoints

| QC Aspect | Test Method | Target Result |

|---|---|---|

| Dimensional Accuracy | Micrometer Calibration | 5mm ±0.1 tolerance |

| Color Uniformity | Pantone comparison | ≤ ±3 variance |

| Heat Resistance | Iron fusion test | Even bonding, no burning |

| Odor Test | Heat exposure | Odor-free |

A seasoned OEM/ODM jewelry manufacturer knows that color consistency is especially sensitive with lighter hues like pastel pink or mint green—minor pigment deviations can affect retail presentation.

Export Documentation and Compliance

When exporting, ensure suppliers provide:

- MSDS certificates for LDPE materials.

- CPSIA compliance (for US educational toy imports).

- EN71 certification for EU children’s products, if relevant.

Comparing Fuse Beads, Alloy Beads, and Brass Components

Although fuse beads belong to a different segment, it’s useful to compare their properties with metals commonly used in jewelry OEM production.

| Material Type | Application | Melting Point | Visual Appeal | Price Range (per kg) | Durability |

|---|---|---|---|---|---|

| Fuse Beads (LDPE) | DIY craft | ~110°C | Matte, flat | Low (USD 4–7/kg) | Moderate |

| Alloy Beads | Fashion jewelry | >600°C | Glossy, metallic | Medium (USD 8–15/kg) | High |

| Brass | Premium jewelry | >900°C | Bright gold-tone finish | High (USD 20–30/kg) | Very High |

Fuse beads are unsuitable substitutes for jewelry metals in appearance or durability but excel in cost-effective creative applications.

Cost Optimization and MOQ Planning for Importers

When planning fuse bead imports:

- MOQ Planning: Standard MOQ = 5,000–10,000 sets; negotiate lower lot sizes for test orders.

- Packaging Selection: Combine pegboards + beads + fusing paper into single retail units.

- Cost Control: Evaluate per-set assembly cost instead of per-bead pricing.

- Logistical Efficiency: Request partial shipments if color assortments exceed container volume.

- Supplier Consolidation: Partner with manufacturers offering full craft accessory sets under one facility to simplify sourcing.

This approach aligns well with private label buyers and wholesalers distributing craft or educational supplies globally.

Trend Overview and Global Market Behavior

Fuse bead crafts experienced strong growth between 2020–2023, driven by:

- Increased home-based crafting trends

- Educational applications promoting fine motor skills

- Social media DIY video popularity

Market Segmentation

| Region | Demand Driver | Typical Buyer |

|---|---|---|

| North America | DIY kits & educational retail | Toy & hobby wholesalers |

| Europe | School craft programs | Stationery distributors |

| Asia-Pacific | Creative hobby culture | Independent craft brands |

Emerging Opportunities

The fusion art segment aligns with creative customization trends, enabling brands to position fuse beads under “mindful crafting” or “family DIY” categories.

For jewelry industry professionals, moving cautiously into fuse bead sourcing can expand product diversity—especially for brands engaged in custom jewelry supply and looking for adjacent categories.

Conclusion

Fuse beads represent a distinctive departure from traditional jewelry beads. While regular beads dominate wearable and decorative applications, fuse beads cater to the growing DIY craft and educational segment. Their low-melting plastic structure defines their creative versatility and heat-fused bonding property—an entirely different aesthetic and engineering principle from metal or glass beads.

For global buyers and fashion jewelry wholesalers, understanding these differences enables more strategic cross-category sourcing. When evaluating fuse bead suppliers, prioritize:

- Certified LDPE materials

- Consistent color calibration

- Reliable OEM/ODM production control

- Comprehensive QC checkpoints

As a long-time jewelry manufacturer, I recommend requesting material test samples before full production approval and validating color precision via Pantone charts. Properly executed, fuse bead imports can enrich your brand’s craft accessory segment and help you enter broader creative markets.

Next Step:

If you’re exploring fuse bead OEM/ODM production or evaluating Chinese suppliers for craft accessory imports, feel free to request a sample kit or catalog—I can share verified supplier recommendations and setup guidance for your next sourcing cycle.