As a jewelry manufacturer working closely with global wholesalers, private label buyers, and design teams, I’ve often witnessed how the right tools and structured materials can transform creative intent into tangible artistry. Jewelry making kits have become a vital component of modern product development – bridging imagination and execution for both aspiring designers and professional sourcing managers. In the B2B sector, especially across fashion jewelry OEM/ODM production lines, these kits serve as testbeds for design validation, craftsmanship training, and prototype development.

Jewelry making kits empower jewelry professionals and product developers to experiment safely with new materials, refine handcraft techniques, and accelerate concept validation. They enable B2B buyers to evaluate design feasibility before committing to mass production, thus enhancing both creative exploration and technical precision.

From OEM jewelry design trials to private label brand development, a well-curated kit offers structured creativity within manageable parameters. It introduces tool handling, material behavior, assembly logic, and aesthetic composition – essentials for professionals seeking to optimize craftsmanship and production efficiency. In effect, these kits become miniature laboratories for jewelry makers and sourcing executives who aim to elevate design quality before scaling to wholesale quantities.

Table of Contents

ToggleHow Can I Choose the Right Jewelry Making Kit for My Product Development Needs?

Selecting the right jewelry making kit goes beyond hobby-level considerations; for B2B jewelry professionals, it’s a strategic sourcing decision. The right kit can help test concepts before investing in mold creation, plating runs, or CAD development. As a jewelry supplier, I always advise partners to approach kit selection with clarity about design goals, target materials, and production volume.

Understanding Your Use Case

Whether you’re designing for stainless steel jewelry production, brass-based costume jewelry, or 925 sterling silver private label lines, the kit you choose must align with the type of jewelry you intend to produce.

- Prototype Design Validation: Choose kits with multiple alloys and findings to test visual appeal and mechanical performance.

- Skill Development Kits: Opt for tool-rich versions when developing internal craftsmanship or training new artisans.

- Material Comparison Kits: Ideal for evaluating finishes, plating quality, and assembly tolerances under real handling conditions.

OEM/ODM Development Perspective

For OEM jewelry buyers who manage sample development, these kits function as a preliminary design lab – allowing faster communication between creative teams and factories. Testing bead arrangements, wire gauges, and clasp mechanisms through kits helps reduce sampling rounds and MOQ risks.

| Kit Type | Ideal For | Benefit for B2B Use |

|---|---|---|

| All-in-One Starter Kit | Brand teams exploring new lines | Quick concept validation; reduces initial sourcing complexity |

| Metalwork Kit | Silver & gold jewelry manufacturers | Learn soldering and shaping to understand casting limitations |

| Beading & Assembly Kit | Fashion jewelry wholesalers | Fast turnaround ideas; easy product refresh prototypes |

| Resin & Epoxy Kit | Trend-based OEM design testing | Perfect for lightweight or translucent jewelry concepts |

Evaluating Supplier Integrity

When sourcing kits from a fashion jewelry wholesale China supplier, prioritize manufacturers who include standardized materials and detailed user manuals. A well-documented kit shows professional integrity and consistency, two factors directly affecting OEM scalability.

What Materials and Tools Should I Look for in a Professional Jewelry DIY Kit?

As someone who regularly audits leading custom jewelry suppliers, I’ve learned that material quality often determines design feasibility. For professional use, a jewelry making kit must include ethically sourced components, industry-grade tools, and plating options that reflect real production standards.

Essential Materials Checklist

The following materials are key for product development teams evaluating design performance or visual aesthetics:

| Material | Durability | Application | Wholesale Suitability |

|---|---|---|---|

| Stainless Steel | Excellent corrosion resistance | Suitable for modern minimalist lines; long life | Best for global distributors and private labels |

| Brass | Good plating adherence | Ideal for affordable fashion jewelry | Cost-effective and highly customizable |

| Zinc Alloy | Moderate durability | Used for experimental prototype designs | Good for short-run testing and ODM collections |

| Sterling Silver (925) | Premium craftsmanship | High-end OEM and luxury collections | Requires careful QC and polishing |

| Resin/Polymer Clay | Lightweight creativity | Great for color experimentation | Ideal for trend testing and visual merchandising |

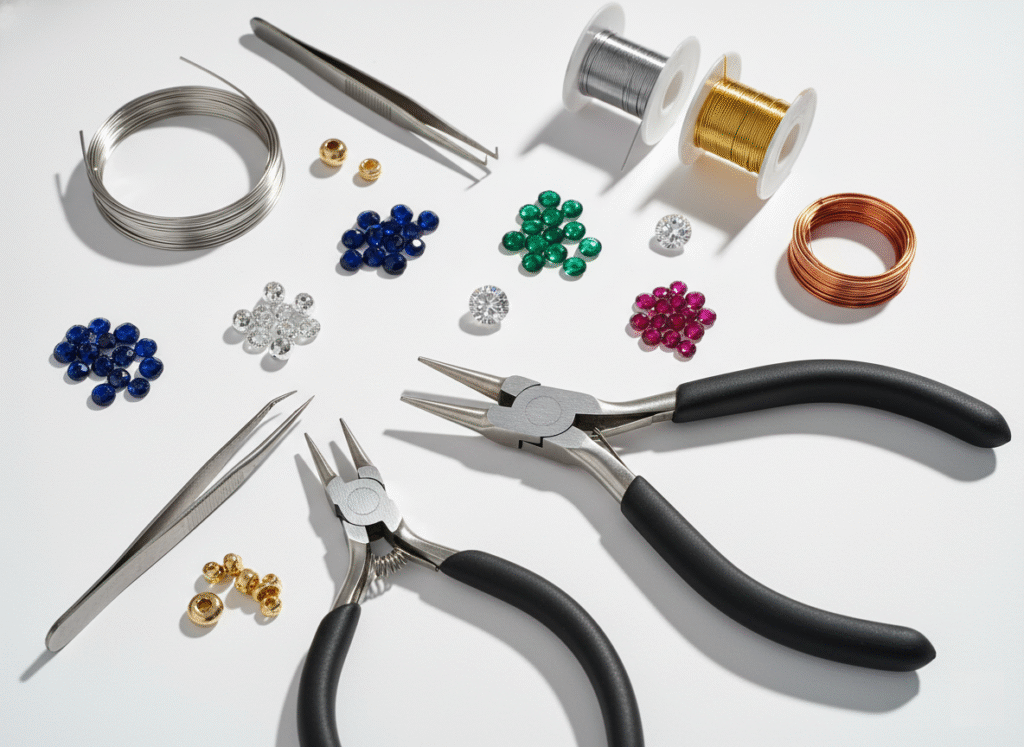

The Tool Kit: What Professionals Need

Professionally oriented kits should include tools designed for precision and longevity. In our manufacturing labs, we use kits equipped with:

- Professional Pliers Set (Round-Nose, Chain-Nose, Flat-Nose) – for all wire manipulation tasks.

- Flush Cutter – essential for clean terminations in stainless steel or brass wire.

- Mandrel & Ruler Tools – for standardized sizing and QC verification.

- Tweezers and Files – improving precision on micro-detail work.

- Mini Butane Torch or Soldering Station (Advanced kits) – for small metal joining tasks during prototyping.

Material Selection for OEM Quality Testing

If you’re a buyer assessing production viability, always test material performance under simulated wear conditions using the kit’s samples. Observe plating adherence, color uniformity, and structural integrity. Kits with nickel-safe plating, PVD coatings, or rhodium finishes closely resemble industrial conditions, making them ideal for supplier audits and QC training.

How Does Using a Jewelry Kit Help Me Design Prototypes for Custom or OEM Jewelry Manufacturing?

Jewelry making kits act as bridge tools between creative ideation and technical manufacturing. For B2B users—especially those working with OEM/ODM jewelry production—these kits offer hands-on insight into assembly logic, tolerance adjustments, and design practicability.

From Concept to Sample: A Controlled Testing Ground

Before requesting factory samples, many design teams use professional kits to simulate the assembly process of pendants, earrings, or bracelets. This tactile learning builds understanding of joining techniques and material compatibility. It allows OEM managers to predict potential bottlenecks during mass production.

Prototype Simulation Strategies:

- Test joining strength between components using different wire gauges.

- Evaluate plating finishes against skin-contact durability.

- Adjust bead spacing or texture patterns based on kit experimentation.

| Prototype Parameter | Small Batch Test via Kit | Expected Factory Impact |

|---|---|---|

| Plating Durability | Use kit samples to test oxidation rate | Reduces rework during plating QA |

| Design Ergonomics | Try assembling pendant loops | Helps refine mold dimensions |

| Bead Arrangement | Adjust color balance manually | Better communication with design engineers |

Facilitating Communication Between Design and Production

In global jewelry supply chains, misunderstandings between creative teams and factories often cause costly sample revisions. By using jewelry kits, buyers can physically express design intent—whether it’s adjusting chain lengths or experimenting with new clasp types. This shared technical vocabulary strengthens OEM collaboration.

Quick Turnaround for Seasonal Collections

When planning upcoming seasonal jewelry drops or trend-based capsule collections, kits allow brand designers to prototype pieces quickly. Once approved, those pieces can transition seamlessly into CAD design or mold creation. This agility translates into better lead-time management and optimized MOQ forecasting.

How Can I Improve My Craftsmanship and Production Efficiency Through Hands-On Jewelry Kit Training?

As a jewelry supplier, I often advocate for “learning through making.” Even established designers benefit from revisiting basics through physical creation. Practicing jewelry assembly with kits builds tangible craftsmanship—a crucial factor for quality control, design precision, and workflow optimization.

Skill Progression Through Repetition

Structured kit training enhances production accuracy. Each assembly cycle improves:

- Tool familiarity: Faster and cleaner manipulations with pliers and cutters.

- Manual dexterity: Reduced error rates when setting small stones.

- Plating awareness: Better understanding of thickness, adhesion, and tone variation.

- Design flow: Intuitive sense of balance and proportion during layout planning.

Professional Development Benefits

For team training or onboarding new artisans in OEM factories:

- Kits serve as cost-efficient practice modules.

- Technicians learn to spot structural weaknesses early.

- QC leaders can establish benchmark visuals using properly assembled kit samples.

- Continuous practice builds operational readiness for faster scaling in wholesale orders.

Integrating Kit Training into Supply Chain Efficiency

When your production team understands design assembly at a granular level, decision-making becomes more efficient:

- Fewer sample revisions, as teams recognize feasibility issues earlier.

- Optimized workflow, guided by hands-on insight from kit experiences.

- Reduced material waste, since testing occurs in small batches before mass production.

- Improved supplier evaluation, through tangible familiarity with component quality.

Collaborating Creatively

Another major advantage is social creativity—especially during OEM joint developments. Kit-based sessions allow designers, engineers, and buyers to collaborate in real-time, each contributing creative and technical insights. This collaborative prototyping accelerates innovation and strengthens buyer-supplier synergy.

Additional Professional Considerations

Quality Inspection and Scaling Up

After learning through kits, apply craftsmanship knowledge directly to QC inspection processes. Focus on:

- Finish Consistency (plating gloss and tone)

- Component Fit (jump rings, clasps, solder joints)

- Structural Soundness (wire stiffness, joint durability)

During mass production audits for fashion jewelry wholesale, trained inspectors who have hands-on kit experience perform with higher accuracy and speed.

Cost Comparison Table: DIY Kit vs OEM Sampling

Understanding cost correlation helps sourcing managers plan smarter.

| Development Stage | Average Cost | Production Outcome |

|---|---|---|

| Jewelry Making Kit (Prototype Phase) | $50–$150 | Creative feasibility testing; zero MOQ risk |

| OEM Sampling (Pre-Production Phase) | $200–$500 per model | Industrial finish validation; MOQ negotiation |

| Full Production (Order Execution) | MOQ 300–1000 pcs | Scalable output; design confirmed through prior kit prototype |

Conclusion: Transforming Creativity into Scalable Craftsmanship

Jewelry making kits serve as more than creative outlets—they’re strategic tools for B2B professionals. They help brands, wholesalers, and OEM buyers deepen their design understanding, enhance craftsmanship, and reduce sourcing risks. Through structured experimentation, these kits transform abstract design intent into actionable, production-ready ideas.

Key Takeaways:

- Use kits to validate material and aesthetic feasibility before investing in molds.

- Prioritize professional-grade materials and tools that mimic real production settings.

- Integrate kit-based learning into staff training and supplier evaluation programs.

- Encourage creative collaboration during prototype trials to unlock innovative designs.

If you’re ready to elevate your jewelry development process, explore premium OEM/ODM jewelry kits from trusted wholesale jewelry manufacturers. Request sample sets or a customized catalog today – and begin transforming ideas into polished, production-ready masterpieces.