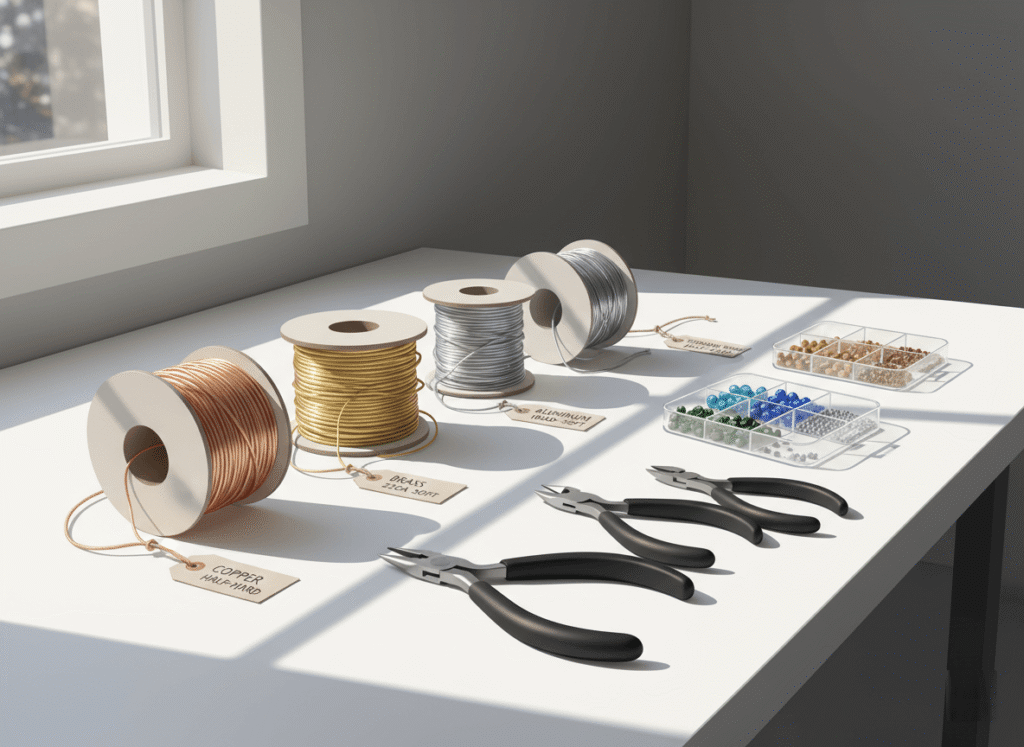

As someone who has worked for years designing and manufacturing fashion jewelry for global retail chains and private label brands, I can tell you that wire selection is far more than just a technical detail — it’s the foundation of every design’s success. Whether you’re a jewelry wholesaler, brand owner, or DIY jewelry studio supplier, understanding how wire types differ can make a dramatic difference in product quality, durability, and overall aesthetic value. The wrong wire choice can lead to tarnishing, weak joints, or poor shape retention, ultimately impacting sell‑through rates and brand reputation. Conversely, the right wire material — whether copper, aluminum, brass, or sterling silver — enables both design flexibility and manufacturing efficiency.

Jewelry wires differ by metal composition, gauge (thickness), hardness (temper), and surface finish.

- Copper and aluminum wires are flexible, inexpensive, and ideal for entry‑level crafting.

- Brass and bronze wires provide a vintage, structural look for statement pieces.

- Sterling silver and gold‑filled wires are premium options for high‑end or private label jewelry lines.

- Wire gauge affects strength and flexibility; hardness determines how well designs hold shape.

Choosing the right combination reduces rework costs, improves plating yield, and enhances customer satisfaction across wholesale and retail markets.

Before investing in crafting sets or sourcing bulk wire from a fashion jewelry wholesale supplier in China, it’s essential to coordinate design intent, production scale, and cost structure. A procurement manager must understand both material science and production practicality — how plating adheres, how wire hardness translates into assembly efficiency, and how color consistency builds brand reliability. In this article, I’ll share insider knowledge to help you source the best wire materials for DIY jewelry crafting, private label production, and wholesale distribution.

Table of Contents

ToggleHow Can I Choose the Right Wire Type for My DIY Jewelry Projects?

Successfully selecting wire for jewelry making hinges on balancing aesthetic preference, design complexity, and production efficiency. From my experience producing both artisan and mass‑market pieces, these decisions always start with three questions:

- What jewelry type is being created — e.g., earrings, bangles, pendants, or wire‑wrapped stones?

- What is the expected price point or brand positioning?

- What level of manual vs. mechanical forming will be used?

Key Considerations in Wire Selection

- Skill level & design goals: Beginners might prefer dead‑soft aluminum or copper, which allows easy bending and reshaping if mistakes occur.

- Durability requirements: Professional or commercial pieces often require half‑hard brass or silver wire, ensuring structure and strength for daily wear.

- Plating compatibility: When working with factory plating lines (vacuum or electrolytic), base metals like brass and copper offer superior bonding strength for gold or rhodium coatings compared to aluminum.

- Color & finish preferences: Choose between natural finishes or pre‑colored anodized wires depending on whether you plan to plate over them.

Table 1: Comparison of Common Jewelry Wire Materials

| Wire Material | Cost Level | Workability | Durability | Plating Adhesion | Common Use Cases |

|---|---|---|---|---|---|

| Copper | Low | Very high | Moderate | Excellent | Practice, weaving, prototypes |

| Aluminum | Low | High | Low–Medium | Poor | Colorful costume jewelry |

| Brass | Medium | Moderate | High | Excellent | Frame structures, vintage looks |

| Sterling Silver | High | Low–Moderate | High | Excellent | Fine jewelry, minimalistic pieces |

| Gold‑Filled | High | Moderate | Very High | N/A | Luxury fashion and demi‑fine jewelry |

| Bronze | Medium | Moderate | Very High | Good | Antique replicas, artisanal styles |

When evaluating OEM or ODM suppliers, request details on wire specifications such as metal purity, gauge range, temper, and available surface treatments. Reliable custom jewelry suppliers will include these in their technical data sheets or plating test results.

What Wire Materials Are Best for Making High‑Quality Imitation Jewelry?

For imitation or fashion jewelry — the largest segment of the global jewelry wholesale market — the best wire is not always the most expensive one, but the one that optimally balances appearance, durability, and affordability.

Copper-based Alloys: Cost-Effective Versatility

Copper remains a cornerstone in fashion jewelry manufacturing because it’s affordable, easily plated, and widely available in multiple gauges. Its high malleability supports easy coiling, wrapping, and soldering — ideal for mass production. However, it oxidizes quickly, so anti-tarnish coatings or plating in gold or rhodium are essential for export-quality items.

Brass and Bronze: Vintage Appeal with Longevity

Brass (copper–zinc alloy) and bronze (copper–tin alloy) are preferred choices when a warmer, vintage aesthetic is needed. Brass wires, slightly stiffer than copper, hold shape better, which minimizes deformation during assembly or shipping. These are the best options for wire structures in statement necklaces or elaborate cuffs. Their superior tensile strength also ensures stable QC performance across large batches.

Aluminum: Lightweight and Colorful

Anodized aluminum wires are frequently used for creative, modern jewelry collections. Their biggest advantage is color diversity — available in vibrant anodic dyes that don’t peel or flake. Though plating adhesion is weak compared to brass, aluminum remains the go-to for DIY wire art and ** costume jewelry**, especially when targeting youth-oriented or festival fashion sectors.

Precious & Premium Wires

- Sterling Silver (92.5% Ag) provides the best brightness and polish quality, ideal for boutique labels or limited‑edition pieces.

- Gold‑Filled Wire offers a generous layer of real gold over brass — typically 5% of total weight — ensuring better wear resistance than standard plating.

These are ideal for demi‑fine jewelry lines, balancing perceived luxury and manageable material cost.

Table 2: Wire Material Comparison for Imitation Jewelry Production

| Property | Copper | Brass | Aluminum | Sterling Silver | Gold‑Filled |

|---|---|---|---|---|---|

| Cost Efficiency | ★★★★★ | ★★★★☆ | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ |

| Weight (Per Meter) | Heavy | Medium | Light | Medium | Medium |

| Tarnish Resistance | Low | Medium | High | High | Very High |

| Color Range | Natural | Golden | Multiple | Bright White | Yellow Gold |

| Ideal for OEM/ODM | Yes | Yes | Yes, for color designs | Yes | Yes |

OEM/ODM Notes:

If sourcing from fashion jewelry wholesale China suppliers, ensure the base metal wire used in plating is lead‑free and nickel‑free, aligning with REACH and CPSIA compliance catalogs demanded by European and US buyers. A reputable stainless steel jewelry manufacturer or custom jewelry workshop will provide composition certificates and colorfastness test reports.

How Do Different Wire Gauges Affect the Durability and Flexibility of My Designs?

Choosing wire gauge directly influences not only design proportions, but also production time, soldering precision, and mechanical reliability of finished items.

Understanding Gauge Measurements

The gauge number corresponds inversely with wire thickness. For example, 18-gauge wire is thicker and stronger than 28-gauge wire. Gauge preferences differ by product type:

| Gauge Range | Typical Diameter (mm) | Recommended Use |

|---|---|---|

| 14–18 | 1.6–1.0 | Bangles, cuffs, frames, clasps |

| 20–24 | 0.8–0.5 | Links, earrings, chain components |

| 26–32 | 0.4–0.2 | Bead wrapping, weaving, delicate detailing |

Application Insights

- Thicker gauges (14–18): Provide structural integrity but require plier leverage or annealing for bending. Perfect for bangles and neck wires.

- Medium gauges (20–24): Ideal all-purpose range for jewelry sets; commonly used for ear hooks, jump rings, and connectors.

- Fine gauges (26–32): Best for wrapping beads, embellishments, or decorative weaves. Expect more flexibility but less support, so it’s best paired with rigid base wires or frames.

Production Efficiency and QC Implications

From a supplier’s perspective, correct gauge choice leads to fewer deformities during electroplating tumbling, consistent ring closure, and better tensile performance in testing. A mismatch in gauge can cause either cracking (too hard) or sagging (too soft) after plating.

Hardness and Temper Categories

| Temper Type | Pliability | Use Case |

|---|---|---|

| Dead Soft | Highly bendable | Intricate wire wrapping, beginner crafting |

| Half Hard | Moderate rigidity | Structural connections, ear wires, links |

| Full Hard | High rigidity | Durable frame jewelry requiring strength |

Pro tip: For production runs above 500 pieces, ordering 50-meter coils of uniform gauge reduces color variance and simplifies QC calibration.

Where Can I Source Wholesale Jewelry Wires and Accessories for Custom Production?

Sourcing high‑quality jewelry wire in bulk demands more than comparing prices — it’s about evaluating material consistency, plating adhesion, MOQ policy, and supplier QC discipline.

Direct from OEM/ODM Factories

Partnering with OEM jewelry manufacturers in China, Thailand, or Turkey offers access to customized gauges and proprietary finishes. These suppliers often process full chain manufacturing — from base metal drawing to plating and packaging — giving you flexibility for private label production.

Key Evaluation Tips for B2B Buyers:

- Verify factory compliance with ISO9001 quality management and nickel‑free plating standards.

- Request small-lot pilot runs before confirming mass orders.

- Ask for technical samples with documentation detailing metal purity, plating thickness (e.g., 0.05‑0.1 microns for gold flash plating), and salt‑spray test results.

Trading Companies and Distributors

For smaller or seasonal purchases, engaging established wholesale distributors in Yiwu or Guangzhou can balance cost vs. convenience. They often offer ready-mixed jewelry wire kits, incorporating copper, aluminum, and brass in multiple gauges. While they lack deep OEM customization, you gain faster lead times and smaller MOQs (100–300 rolls).

Material-Specific Suppliers

If your brand’s strategy emphasizes longevity and hypoallergenic performance, consider stainless steel wire suppliers or nickel‑free brass wire producers. Stainless steel requires specialized machinery for bending due to hardness, but offers unmatched tarnish resistance, making it ideal for global e‑commerce brands seeking low return rates.

Supplier Checklist Before Importing

| Checklist Item | Why It Matters |

|---|---|

| Material Certificates | Confirms purity and metal compliance (lead/nickel-free) |

| Gauge & Hardness Reports | Ensures consistency across batches |

| Plating Quality Audit | Prevents uneven color or blistering issues |

| MOQ & Production Lead Time | Assists planning seasonal drops or promotions |

| Packaging & Labeling Options | Supports brand differentiation and resale presentation |

Cost Control and MOQ Planning

When planning wholesale jewelry wire procurement, negotiate per‑meter pricing based on anticipated coating weight and MOQ thresholds. Factories usually offer:

- Tiered cost discounts (e.g., 5% off per additional 1000 meters)

- OEM customer branding for spools or cartons

- Mixed metal bundles to test emerging designs before large commitments

For efficient supply chain planning, align material orders with seasonal trend forecasts — for example, warm brass tones dominate autumn/winter, while rose-gold-plated copper sees high rotation in spring/summer collections.

Additional Insight: The Rise of Eco-Friendly Jewelry Wires

Modern buyers increasingly ask for recycled metals and eco-conscious plating. Forward-thinking suppliers now offer recycled copper wire and low-impact silver alloys certified under RJC (Responsible Jewellery Council) standards. Choosing such options adds tangible marketing value while supporting sustainable sourcing narratives critical in B2B apparel and accessories catalogs.

| Eco Option | Description | Benefit |

|---|---|---|

| Recycled Copper | Derived from post-industrial scrap | Reduces cost & supports CSR |

| Bio-Based Coatings | Plant-based sealing instead of polyurethane | Safer environmental compliance |

| Low-Leaded Brass | Brasses with <0.1% lead | REACH-compliant for EU market |

Conclusion

In the world of fashion and imitation jewelry manufacturing, wire type is the unseen pillar behind every beautiful creation. Understanding differences in metal composition, gauge size, and temper hardness not only enhances craftsmanship but also streamlines production cost and complaint-free export.

- Copper and brass remain dependable for volume fashion assortments.

- Sterling silver and gold‑filled wires elevate luxury collections.

- Aluminum balances creativity and budget for colorful, lightweight ranges.

When choosing your wholesale jewelry wire supplier, prioritize:

- Consistent plating and alloy purity records.

- Strong communication about gauge customization and MOQ flexibility.

- Compatibility with your target market’s regulations (lead‑free, nickel‑free, REACH, etc.).

If you’re seeking to expand your custom jewelry production or upgrade your existing crafting sets, now is the ideal moment to request metal samples, assess tensile and plating tests, and align with a trusted OEM partner. Doing so will help you build not just a product line but a brand that shines — consistently, confidently, and profitably.

Next Step:

Contact your OEM/ODM jewelry manufacturer today to request a sample kit of copper, brass, and gold-filled wires. Evaluate their plating finish, flexibility, and tensile strength before scaling into full production. Your next best-selling collection begins with the perfect wire.