As a jewelry manufacturer who has spent years collaborating with global wholesalers and private label brands, I’ve seen many buyers struggle with the decision between DIY bead kits and pre-designed jewelry sets. The choice might seem simple on the surface, but in the B2B jewelry industry—where margins, customization, and production efficiency matter—the implications go far beyond craft preferences. Whether you’re sourcing for a brand’s creative team, managing procurement for an e-commerce retailer, or developing your next private label line, understanding the nuances between DIY beading kits and ready-made options can transform your sourcing strategy and production outcomes.

DIY bead kits deliver complete creative control, lower long-term costs, and the flexibility to tailor unique pieces for brand differentiation. Pre-designed kits, on the other hand, ensure speed, convenience, and consistent quality through pre-curated, ready-to-assemble components. The best choice depends on your product line goals—customization vs turnaround time—and internal production capabilities, including design expertise, assembly labor, and packaging resources.

Strategically, this choice ties into broader supply chain considerations. For private label jewelry manufacturers, opting for DIY kits may improve creative freedom but require tighter control over material sourcing, color consistency, and QC. Meanwhile, pre-designed kits simplify logistics, streamline production scheduling, and allow scalable, standardized output for high-volume orders. Understanding these trade-offs enables better MOQ planning, cost control, and alignment with your target market—whether you serve retailers seeking quick turnover or designers pursuing exclusive product aesthetics.

Table of Contents

TogglePre-Designed Bead Kits: Convenience and Scalability in Jewelry Production

Streamlined Manufacturing for Bulk Orders

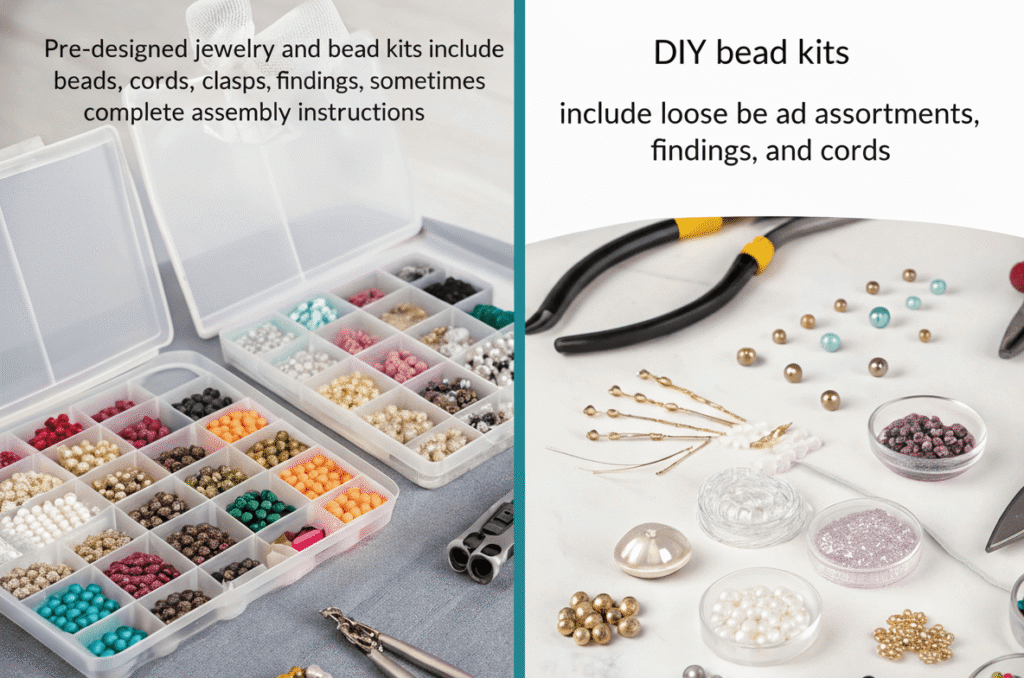

Pre-designed jewelry and bead kits are a cornerstone for wholesalers and retail brands looking to optimize turnaround time and maintain quality consistency. As a jewelry supplier, I often recommend this option to buyers who value efficiency and predictability. These kits include all components—beads, cords, clasps, findings, and sometimes complete assembly instructions—allowing immediate production without design delays.

Why B2B Buyers Prefer Pre-Designed Kits

- Low Labor Input: Ideal for mass production where time equates to cost. Workers can follow standardized assembly instructions, keeping labor hours predictable.

- Stable Quality Output: Since bead sizes, finishes, and colors are pre-coordinated, visual consistency is guaranteed across batches.

- Simplified Procurement: Buyers receive an all-inclusive SKU that minimizes supplier management complexity—no need to source separate beads or findings from multiple vendors.

- Faster Product Launches: Pre-designed kits enable immediate rollout for seasonal collections, test markets, or promotional gifts.

- Training & Skill Accessibility: Even low-skill assembly teams can effectively execute projects without extensive design training.

OEM/ODM and Private Label Potential

For private label buyers, pre-designed bead kits can be semi-customized through OEM/ODM jewelry production. You can modify aspects like:

- Logo engraving or branded packaging

- Custom color combinations

- Alternative metals or plating styles

- Pack size and presentation format

These configurable elements preserve the efficiency of pre-design while granting necessary brand distinction—a crucial balance in the competitive fashion jewelry wholesale China landscape.

Material and Plating Comparison Table

| Type of Pre-Designed Kit | Typical Metal Base | Plating Method | Production Complexity | Ideal MOQ Range |

|---|---|---|---|---|

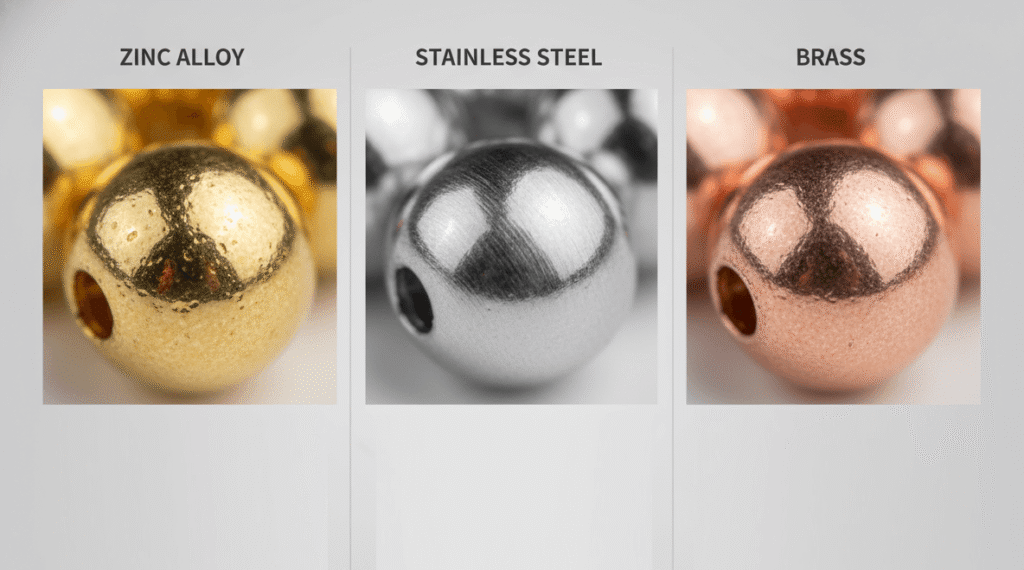

| Alloy-based bead kits | Zinc alloy | Electroplating (gold/silver tone) | Low | 200–500 sets |

| Stainless steel bead kits | 304/316L steel | PVD coating | Medium | 100–300 sets |

| Brass luxury kits | Brass core | Genuine gold plating | High | 50–150 sets |

Drawbacks for Manufacturers

While pre-designed bead kits offer scalability, they do limit creative range. Certain clients find it challenging to differentiate their product lines from competitors using similar supplier catalogs. Additionally, you’re paying for convenience—costs per piece are higher due to curated design, assembly preparation, and packaging labor. For large-volume brands, balancing these cost implications with market pricing becomes crucial.

DIY Bead Kits: Flexibility, Customization, and Creative Autonomy

The Power of Bulk Sourcing and Design Freedom

DIY bead kit sourcing appeals to creative brands and artisan-focused wholesalers that prioritize unique jewelry designs and creative flexibility. Instead of purchasing fully curated kits, buyers procure loose bead assortments, findings, and cords—either directly from custom jewelry suppliers or general wholesale bead distributors.

Advantages for Private Label Buyers and Designers

- Unlimited Customization: DIY kits allow full control over color palettes, bead compositions, and design aesthetics—enabling each brand to achieve distinctive product storytelling.

- Cost Efficiency Over Time: Bulk procurement of loose materials minimizes per-unit costs. Brands producing multiple SKUs from shared materials achieve strong economies of scale.

- Creative Upskilling: Designers and assembly teams gain material literacy—learning how different beads interact with light, layering, and pattern formation.

- Adaptive Product Lines: DIY setups allow fast design iteration for trend-responsive inventory, ideal for fashion-forward collections.

Materials and Quality Considerations

One of the greatest challenges for DIY jewelry kit manufacturers is maintaining bead quality and color consistency when assembling materials from diverse sources. Stainless steel and alloy beads may differ in finish, plating thickness, or dimensional tolerance depending on the supplier.

Material Comparison Table

| Material Type | Durability Level | Tarnish Resistance | Weight | Price Range/1000 pcs | Typical Use |

|---|---|---|---|---|---|

| Stainless Steel | Excellent | High | Medium | $30–$60 | Premium fashion jewelry |

| Brass | High | Medium | Heavy | $40–$80 | Luxury pieces |

| Alloy | Moderate | Low–Medium | Light | $15–$30 | Trend-based, short-term jewelry |

This material analysis is central to planning your MOQ and cost estimation. Buyers who master this matrix can strategically balance premium vs standard materials within multi-tier product lines.

Creative and Operational Challenges

DIY sourcing requires strong design coordination:

- Color Matching: Ensuring beads from different suppliers maintain the same tone under different lighting palettes.

- Bead Sizing Uniformity: Even minor dimensional deviations can affect lineup symmetry and finished product aesthetic.

- QC Burden: The manufacturer bears full responsibility for rejecting inconsistent lots before assembly.

These responsibilities demand a well-organized workflow—with cataloged bead inventory, material testing standards, and trained artisans to execute complex designs consistently.

Production and Packaging Considerations: From Design to Market Shelf

OEM/ODM Production Options for Pre-Designed Bead Kits

When sourcing from China or Southeast Asia’s jewelry manufacturing hubs, B2B buyers can request a spectrum of production and packaging options tailored to brand positioning:

| Packaging Option | Description | Branding Feasibility | Cost Impact |

|---|---|---|---|

| Poly bag with header card | Simple, low-cost packaging for retail kits | Moderate | ★☆☆☆☆ |

| Branded gift box set | Premium packaging for e-commerce ready sets | High | ★★★★★ |

| Recyclable paper envelope | Sustainable choice for eco-conscious buyers | Medium | ★★★☆☆ |

| Individual component compartment | Ideal for DIY sets allowing bead sorting | Medium | ★★★★☆ |

Manufacturers often provide sample mockups for packaging before production approval. As a supplier, I recommend testing packaging combinations with your distribution team to ensure protection during transit and visual appeal for online listings.

Quality Control and Inspection Criteria for Bulk Orders

Whether producing DIY components or pre-designed kits, QC remains non-negotiable. In my factory’s experience, buyers who define precise inspection metrics early dramatically reduce post-shipment disputes.

Recommended QC Parameters:

- Bead Sizing Accuracy: ±0.1mm tolerance for premium lines

- Plating Adhesion Test: Acid-resistance check ensuring no fading after 48-hour exposure

- Color Consistency: Visual comparison under standardized LED and daylight

- Assembly Strength: Tensile test for thread and clasp durability

Executing a sample QC checklist with every new batch helps achieve reproducibility across thousands of units—building buyer trust and minimizing return rates.

Supply Chain and Market Trend Insights

Cost Control and MOQ Planning

From a B2B perspective, MOQ is more than just a manufacturing constraint—it’s a strategic lever for cost optimization.

- DIY Kits: Lower MOQ achievable per material type since leftovers can be reused across multiple SKUs.

- Pre-Designed Kits: Require higher MOQ per design to justify tooling, plating, and packaging costs.

As global freight costs continue fluctuating, consolidating materials by category (e.g., all brass beads across designs) may help achieve economies of scale without sacrificing diversity.

Market Behavior and Trend Evolution

Fashion jewelry trends evolve rapidly—mirroring seasonal palettes, influencer styles, and retail demands. DIY kits increasingly appeal to niche creative brands and hobbyist markets that crave personalization. Conversely, pre-designed kits dominate mass merchandising platforms like Amazon or Temu, where consumers prioritize convenience and quick assembly.

For private label buyers or jewelry wholesalers, the hybrid sourcing model—pre-designed base kits with supplemental DIY accessory packs—offers the agility to adapt to market cycles without reinventing your entire supply chain.

Conclusion: Strategic Takeaways for Jewelry Industry Buyers

Choosing between DIY and pre-designed bead kits is ultimately a balance between creative freedom and operational consistency. Pre-designed kits serve efficiency-oriented buyers demanding predictable outputs and swift delivery times. DIY kits empower design-driven brands to innovate but require tighter materials control and skilled labor planning.

Key sourcing insights:

- Assess goals: innovation vs scalability

- Define design capability: in-house designers vs outsourcing pattern creation

- Evaluate supplier QC processes early

- Align MOQ and packaging with channel strategy

For new buyers or seasoned sourcing managers, start by sampling both paths. Request a small trial batch of DIY materials to test assembly performance, alongside a run of pre-designed kits to evaluate packaging appeal and yield accuracy. Compare outcomes, then scale your preferred model for sustained growth.

Ready to explore hybrid jewelry kit solutions?

Connect with a professional stainless steel jewelry manufacturer or custom jewelry supplier to review live samples, plating options, and OEM packaging possibilities today. Selecting the right supplier can unlock efficiency, creativity, and brand alignment—all while maintaining competitive wholesale margins.