In today’s fashion accessory market, jewelry bead kits have become a cornerstone for both DIY creators and professional designers seeking to expand their collections efficiently. For jewelry wholesalers, brand owners, and private label sourcing managers, understanding the materials used in bead kits is crucial for maintaining product quality, design consistency, and consumer appeal. Whether you are sourcing from a stainless steel jewelry manufacturer or a custom jewelry supplier in China, material selection directly impacts the durability, plating quality, and perceived value of your finished pieces.

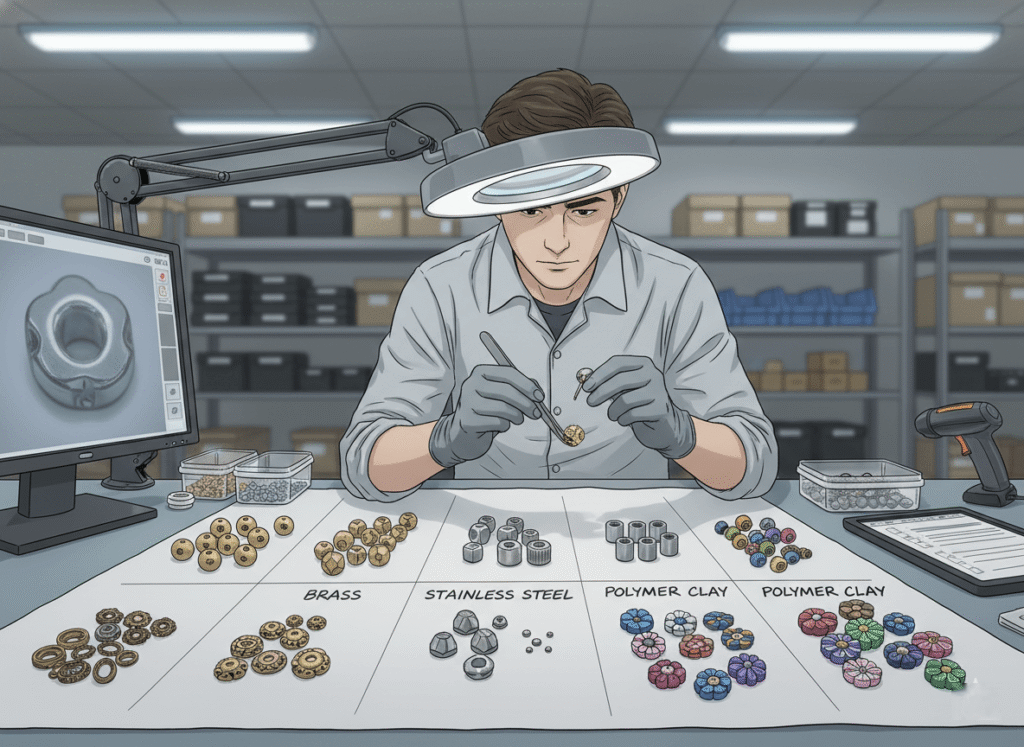

High-quality jewelry bead kits typically feature glass, metal, gemstone, acrylic, wooden, ceramic, and polymer clay beads, paired with durable threading and professional finding. When sourcing, prioritize suppliers offering OEM/ODM capability, consistent plating and QC standards, and a transparent material composition report. Stainless steel, brass, and zinc alloy remain top metal materials for durability and hypoallergenic properties.

As a fashion jewelry wholesale supplier, I’ve seen firsthand how material selection shapes brand reputation and market competitiveness. In this article, I’ll walk you through the most common materials found in bead kits, explain how to identify quality, and guide you toward sourcing the right OEM or private label partner in China. You’ll also learn how materials influence plating quality, craftsmanship level, and consumer experience across varying product tiers—from affordable fashion kits to high-end gemstone collections.

Table of Contents

ToggleOverview of Materials Used in Jewelry Bead Kits

The foundation of a successful bead jewelry line lies in understanding the diverse materials that compose each kit. In B2B sourcing, this knowledge helps determine MOQ planning, unit cost, and brand alignment with target market segments.

Common Material Categories

| Material Type | Characteristics | Ideal Use Case | Price Range |

|---|---|---|---|

| Glass Beads | Uniform size, rich color range, and glossy finish | Everyday fashion, decorative beadwork | Low to Mid |

| Plastic Beads | Lightweight, cost-effective, great for children’s kits | Entry-level, seasonal hobby kits | Low |

| Metal Beads | Durable, elegant, available in polished or antique plating | Premium bracelets, statement necklaces | Mid to High |

| Gemstone Beads | Natural aesthetic, perceived value, unique patterns | Boutique jewelry, semi-precious collections | High |

| Wooden Beads | Eco-friendly, organic texture | Bohemian, rustic, summer collections | Mid |

| Acrylic Beads | Lightweight, imitates glass brightness | Trendy fast fashion styles | Low to Mid |

| Ceramic Beads | Artisanal feel, handcrafted uniqueness | Limited edition, handmade look | Mid to High |

| Polymer Clay Beads | Fully customizable, various shapes and designs | DIY collections, colorful artisan lines | Mid |

| Shell/Pearl Beads | Natural gloss, coastal luxury vibe | Resort wear, luxury brands | High |

Identifying High-Quality Materials for Wholesale Jewelry Bead Kits

As a jewelry manufacturer, I often emphasize that identifying high-quality materials begins before you even sample the product. Reliable suppliers not only provide consistent color, shape, and plating finish—but also specify what base metal and coatings are used.

Visual and Physical Inspection Standards

- Surface Consistency: Examine beads under uniform light for micro-scratches, cloudiness, or uneven coating.

- Weight and Texture: Higher-density glass, metal, and gemstone beads typically feel heavier and smoother.

- Color Stability: Run a simple acetone wipe test on plated or painted beads. Fading or color residue signals inferior plating.

- Thread Hole Precision: Uneven holes can cause stringing complications and breakages during bulk assembly.

QC Criteria for B2B Bulk Inspection

When conducting third-party QC on bead kits, I ensure consistency in the following key areas:

| Inspection Category | QC Standard | Notes |

|---|---|---|

| Material Uniformity | ±3% variance in bead size | Essential for professional assembly |

| Plating Thickness | ≥0.03 μm for flash, ≥0.1 μm for high-end finish | Affects longevity and tarnish resistance |

| Nickel/Lead-Free Certification | SGS or Intertek compliance | Needed for EU/US market |

| Threading Material Quality | No fraying, tested tensile strength | Especially for elastic cords |

| Pack Consistency | No bead color mixing or missing items | Important for retail readiness |

Supplier Transparency Indicators

- Detailed material disclosure sheets (e.g., stainless steel 304/316L, brass CuZn ratio).

- Batch plating records documenting electrolyte composition.

- Access to factory audit reports.

- OEM/ODM design capabilities with in-house tooling and mold development.

When these documentation standards are met, it signals a mature, export-ready manufacturer aligned with global B2B expectations.

Selecting Beads for Durability and Hypoallergenic Performance

One of the top priorities among brand owners and private label sourcing teams is ensuring hypoallergenic quality and long-term durability, especially for jewelry pieces worn on skin.

Comparison of Common Bead Materials

| Material | Durability | Hypoallergenic | Cost Efficiency | Sourcing Note |

|---|---|---|---|---|

| Stainless Steel (304/316L) | ★★★★★ | ★★★★★ | ★★★ | Excellent for premium kits; corrosion-resistant |

| Brass (Copper-Zinc Alloy) | ★★★★ | ★★★ | ★★★★ | Warm appearance; may tarnish without coating |

| Zinc Alloy | ★★★ | ★★ | ★★★★★ | Most affordable option for large volume orders |

| Sterling Silver (Ag 925) | ★★★★★ | ★★★★★ | ★★ | Ideal for boutique collections |

| Aluminum | ★★ | ★★★★ | ★★★★ | Lightweight and tarnish resistant |

| Plastic/Acrylic | ★★ | ★★★★★ | ★★★★★ | Best for budget-friendly kits or children’s lines |

How to Ensure Hypoallergenic Quality

- Prefer nickel-free plating solutions, especially for North American and European markets.

- Request MSDS (Material Safety Data Sheets) to verify alloy composition.

- For gold-plated beads, insist on PVD (Physical Vapor Deposition) or IP plating, which is far stronger than electroplating.

Material Influence on Plating & Finishing

Different bead bases respond uniquely to plating:

| Base Material | Plating Compatibility | Recommended Coating | Result |

|---|---|---|---|

| Brass | Excellent | 14K/18K Gold, Rhodium | Deep luster and strong adhesion |

| Stainless Steel | Excellent | IP Gold, Black Ion | Durable, scratch-proof |

| Zinc Alloy | Fair | Flash Gold, Silver | Economical but short lifespan |

| Copper | Excellent | Rose Gold | Warm tone and excellent conductivity |

High-end buyers and retail chains often prioritize plating uniformity and corrosion resistance, as these directly affect resale value and long-term brand reputation.

OEM/ODM Custom Bead Kit Manufacturing in China

Having worked directly with custom jewelry suppliers in major Chinese manufacturing hubs like Guangzhou and Yiwu, I can attest that OEM/ODM production provides unmatched flexibility for brand differentiation.

What to Expect from a Reliable OEM/ODM Jewelry Partner

- In-house Design Assistance: CAD design for bead molds and packaging layouts.

- Material Sample Approval: Physical or photo proofs before final production start.

- Low MOQ Planning: Tailored quantities for start-up brands or pilot markets.

- Consistent Lead Time: Average 25–40 days depending on order size.

- Global Compliance: Certifications for environmental plating processes (RoHS, REACH).

Evaluating Supplier Infrastructure

| Evaluation Aspect | What to Check | Impact |

|---|---|---|

| Material Sourcing System | Local feeding network for glass, metal, and gemstone components | Determines flexibility & cost |

| Production Capabilities | CNC cutting, hand-polishing, and in-house plating | Ensures consistent quality |

| QC & Sampling | Pre-shipment random sample inspection (AQL 1.0–1.5) | Reduces return rate |

| After-Sales Policy | Replacement guarantee for defective batches | Builds long-term B2B reliability |

Proven Sourcing Hubs and Recommendations

- Yiwu City – Best for acrylic, plastic, and resin bead kits with flexible MOQs.

- Guangzhou – Specialized in stainless steel and brass jewelry assemblies.

- Dongguan – Known for precision mold development and OEM engineering.

- Shenzhen – Focused on high-end plating, gemstone, and pearl-based products.

Identifying the right region can drastically reduce logistics costs and communication time.

The Impact of Material Choices on Product Marketability

B2B buyers often underestimate how material choice dictates not just price, but also brand positioning and consumer perception.

Market Behavior and Trend Analysis (2024–2025)

- Sustainability: Demand for eco-friendly bead materials (wood, recycled glass, and hypoallergenic metals).

- Vegan & Natural Aesthetic: Growth in natural stone and shell bead kits for conscious consumers.

- Personalization: OEM-friendly polymer clay and acrylic options enable custom branding.

- Minimalist Durability: Stainless steel remains dominant due to longevity and unisex appeal.

Cost Control in Material Selection

| Material Group | Cost Category | Recommendation |

|---|---|---|

| Entry-Level Kits | ≤ $0.10 per bead | Focus on acrylic, plastic, and coated alloy |

| Mid-Tier Kits | $0.10–$0.30 per bead | Combine glass with electroplated brass |

| Premium Kits | ≥ $0.50 per bead | Include gemstones, freshwater pearls, or stainless steel |

For scalable private label production, mixing 2–3 material types in one collection helps balance cost without sacrificing visual quality.

Table: Quick Reference for Buyer Material Selection Strategy

| Objective | Recommended Material | Ideal Supplier Type | Key QC Focus |

|---|---|---|---|

| Entry-level retail kits | Acrylic, plastic | ODM – Yiwu region | Color accuracy |

| Eco-friendly collections | Wood, clay, recycled glass | OEM – Zhejiang factories | Specific certification |

| Premium retail jewelry | Brass, stainless steel, gemstones | OEM – Guangdong | Plating thickness, anti-tarnish test |

| Hypoallergenic designs | 316L stainless steel | OEM partners | Nickel release test |

| Luxury capsule launches | Pearl, silver, gold-filled | Shenzhen design studios | Surface gloss and matching |

Recommended Sourcing Practices

Supplier Vetting Checklist

- Request sample bead kits for tactile evaluation.

- Ensure factory photos/videos show polishing and plating workshops.

- Review lead times (ensure flexibility during high season).

- Ask for third-party test results (salt-spray, nickel release, adhesion).

- Always perform a trial order before full commitment.

Logistics and MOQ Control

- Bundle similar kits to reduce freight cost per unit.

- Plan for MOQ ranges between 300–1000 sets per design.

- Consider drop test or shipping simulation to assess packaging durability.

Conclusion

In the world of fashion jewelry sourcing, understanding the materials behind bead kits is more than a technical detail—it’s a foundation for brand credibility and customer satisfaction. From glass and polymer clay to stainless steel and gemstones, each material offers unique strengths that cater to different audience tiers and price brackets. The key for B2B buyers lies in balancing material quality, plating performance, and supply chain reliability.

When choosing an OEM/ODM jewelry partner in China, prioritize those with in-house plating, strict QC standards, and certified hypoallergenic materials. This ensures your brand remains competitive, compliant, and consistent across global markets.

If you’re exploring new suppliers or seeking to develop your own custom jewelry bead kit line, I recommend starting with small-batch prototypes. Request material samples, evaluate plating finishes firsthand, and only then scale to full production. Connect with reliable wholesale jewelry manufacturers who specialize in stainless steel, brass, and premium mixed-material bead kits — and you’ll secure both product quality and brand trust in today’s fast-evolving accessory market.

Ready to start sourcing?

Request a sample or explore our OEM/ODM bead kit catalog today—discover materials that match your brand’s vision and market demands.