Creating compact, lightweight, and safe craft kits designed for on-the-go creativity is not only a growing trend among retail consumers but also a lucrative opportunity for jewelry manufacturers, wholesalers, and private label suppliers. As a jewelry manufacturer myself, I’ve seen an increasing number of B2B clients—especially lifestyle brands, DIY retailers, and tourism-focused gift companies—request portable kits that support creativity during travel. These kits serve as excellent promotional items, online subscription box content, or retail shelf products for travel-oriented audiences looking for convenience and engagement.

To create successful travel-friendly craft kits, focus on lightweight materials, compact packaging, and compliant components. Choose mess-free, non-electrical items such as pre-cut jewelry wires, stainless steel findings, or eco-friendly beads. Package these in resealable tins or zip pouches with clear illustrations for use without internet access. Partnering with reliable OEM/ODM jewelry manufacturers in Chin guarantees efficient production at scale with international safety compliance and quality control.

In this guide, I’ll share actionable strategies—from material sourcing to packaging design and supplier selection—so jewelry wholesalers and brand owners can confidently launch travel-ready craft kits. Whether you aim to sell DIY jewelry sets in airport boutiques, design kits for tourism retailers, or include them in holiday gift assortments, understanding manufacturing specifications, QC standards, and materials optimization will be crucial to staying competitive globally.

Table of Contents

ToggleSelecting Lightweight Jewelry-Making Materials

When making travel-friendly craft kits, choosing materials that balance durability and portability is essential. For global distributors and sourcing managers, optimizing each gram of product weight translates to lower shipping costs and increased customer usability.

Prioritizing Stainless Steel, Brass, and Alloy Components

For compact kits, stainless steel jewelry components are the top choice. They’re corrosion-resistant, hypoallergenic, and light enough to pack efficiently. Brass and zinc alloy are also viable for cost-sensitive projects, though they may need higher plating protection in tropical travel conditions.

| Material | Durability | Weight | Corrosion Resistance | Cost Level | Ideal Use |

|---|---|---|---|---|---|

| Stainless Steel | Excellent | Light | High | Medium | Travel jewelry kits, waterproof accessories |

| Brass | Good | Moderate | Medium | Low | Compact charm kits |

| Zinc Alloy | Fair | Moderate | Low | Low | Budget craft kits |

As a custom jewelry manufacturer, I recommend 304 or 316L stainless steel for charm bracelets, pendants, and chains in travel kits. Unlike base metal alloys, steel doesn’t tarnish easily—particularly when subjected to moisture or temperature changes during transit.

Selecting Mess-Free and Safe Craft Elements

Travel convenience depends on materials that minimize risk and mess:

- Include pre-measured bead sets or small wire spools.

- Replace liquid adhesives with solid wax thread conditioners or adhesive dots.

- Avoid sharp tools; use rounded-tip pliers or mini tweezers compatible with TSA restrictions.

- Opt for snap-together charm connectors rather than traditional jump rings.

In B2B production, these small design changes drastically reduce cross-border logistics complications and enable compliance with airline safety requirements worldwide.

Designing Portable and Secure Packaging

Packaging is more than visual appeal—it determines how easily customers can travel with or store the kit. As an ODM supplier, I often see packaging overlooked in early design phases, but it directly influences product usability and brand perception.

Compact and Reusable Containers

The ideal travel craft kit packaging should be:

- Compact: fits in a handbag or carry-on

- Durable: resists bending and spillage

- Reusable: doubles as storage for future projects

Great options include mini tins, resealable kraft bags, or snap-lid boxes. Brands seeking eco-appeal may prefer biodegradable polymer containers or recycled cardboard sleeves.

| Packaging Type | Portability | Sustainability | Branding Surface |

|---|---|---|---|

| Metal Tin | High | Moderate | Medium |

| Kraft Pouch | Excellent | High | High |

| Plastic Organizer Box | Moderate | Low | High |

| Biodegradable Box | Good | Excellent | Medium |

For OEM jewelry kits, I often recommend adding custom stickers or embossed logos on tins. This provides branding visibility without extra printing logistics while maintaining portability. Buyers can also request velvet mini bags or polypropylene zip locks for premium aesthetic and lightweight structure.

Including Instructions and User-Friendliness

Every craft kit should include illustrated guides, ideally printed in waterproof mini booklets or as foldable cards. The aim is to ensure your customers can craft even without internet access or video tutorials.

As a B2B provider, I often integrate multilingual guides depending on export market destination—English for Europe and America, Spanish for Latin America, and Japanese for East Asia retail distribution.

Meeting International Quality and Safety Standards

For brand owners selling globally, compliance determines long-term viability. Travel craft kits containing jewelry-making items must meet safety standards—particularly regarding metal content, plating quality, and small-parts child safety laws.

Core Compliance Focus Areas

- Nickel, Lead, and Cadmium Testing:

Ensure all metal parts meet EU REACH and US CPSIA standards.

Partner with factories offering official SGS or BV testing certificates. - Plating Quality and Durability:

For small kits, use PVD or electroplated surfaces that resist oxidation—ideal for multi-climate travel conditions.

| Plating Type | Durability | Gloss Finish | Eco-Friendliness | Typical Lifespan |

|---|---|---|---|---|

| PVD (Physical Vapor Deposition) | Excellent | High | High | 2–3 years |

| Electroplating | Good | Moderate | Medium | 1–2 years |

| Ion Plating | Excellent | High | Moderate | 3+ years |

- Component Safety for Travel:

Skip sharp tools. Replace with child-friendly assembly items: screw clasps, elastic cords, and soft bead mats.

This ensures compliance with airline carry-on policies and international toy safety guidelines if targeting family travel markets.

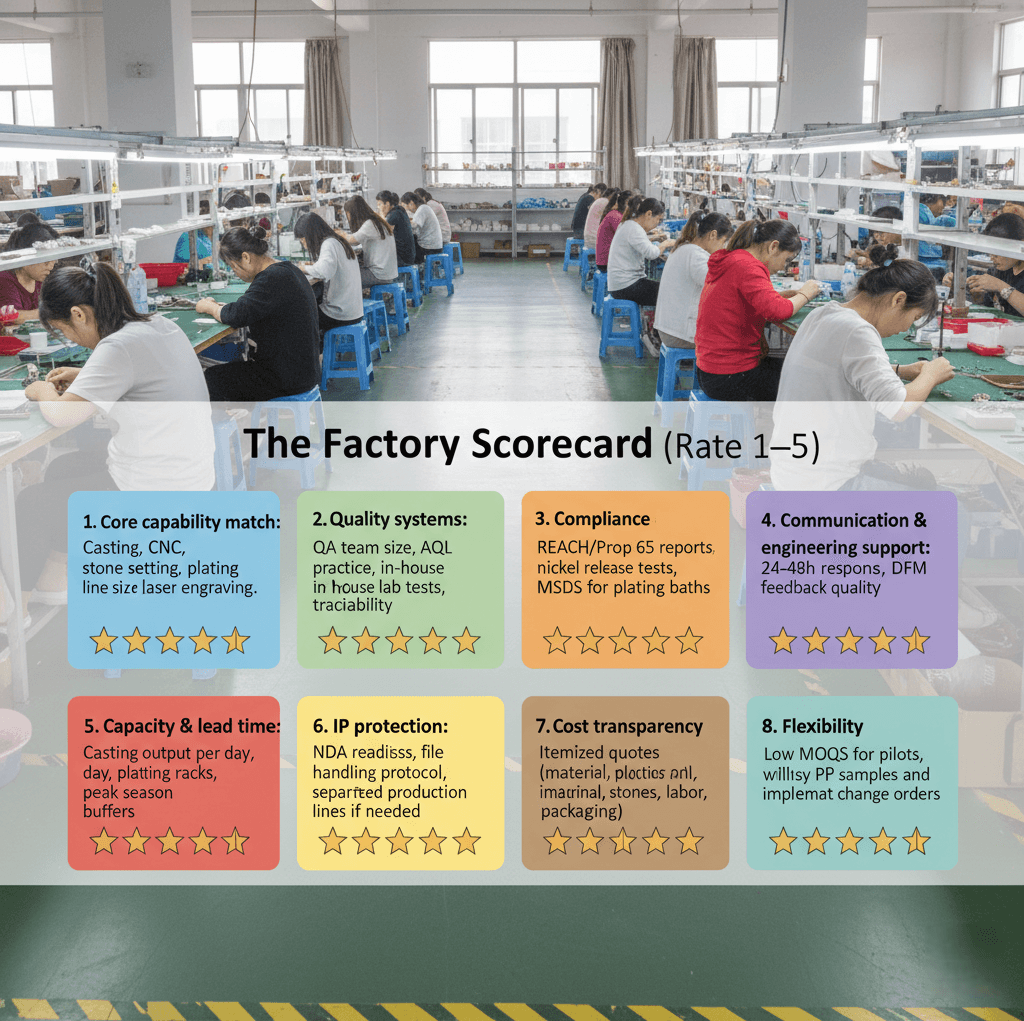

QC Standards and Inspection Protocols

When producing through OEM suppliers in China, standard quality inspection should include:

- Material verification (alloy composition, plating thickness)

- Dimensional check (component fit accuracy)

- Functional test (fastener strength, elasticity)

- Packaging durability evaluation (drop and compression resistance)

In my factory routine, each bulk order undergoes three stages of QC:

- Pre-production inspection (PPI) – raw materials and plating.

- During-production inspection (DPI) – semi-finished kit assembly.

- Final random inspection (FRI) – packaging stability and labeling accuracy.

By following these steps, B2B buyers ensure their travel kits maintain global compliance—and avoid major brand liability issues overseas.

Sourcing Reliable OEM/ODM Suppliers in China

China remains the leading hub for fashion jewelry wholesale production and custom craft kit sourcing. The key for travel-kit suppliers is finding manufacturers experienced in small-scale product assembly and international logistics coordination.

Identifying the Right Factory Partner

When selecting a supplier:

- Seek factories that offer both jewelry component manufacturing and kit assembly services under one roof.

- Cross-check MOQ flexibility—small batch production reduces inventory pressure for niche travel markets.

- Confirm capability for eco-material certifications (RPET packaging, vegan leather cords, lead-free metals).

- Review their logistics support—including secure export packing aligned with DDP or FOB shipments.

Cost Planning and MOQ Management

If you’re launching a new line, start with low MOQ (300–500 units) to test sell-through rates before scaling.

Use the following cost framework to guide vendor negotiations:

| Production Element | Typical Cost Range (USD/Unit) | Negotiation Tips |

|---|---|---|

| Metal Components | 0.15–0.35 | Request tier-based cost discounts beyond 1K units |

| Packaging | 0.25–0.60 | Source locally for faster redesign cycles |

| Instruction Insert | 0.05–0.15 | Automate printing with variable QR codes |

| Assembly Labor | 0.10–0.30 | Combine component tasks under single vendor for efficiency |

As a supplier with decades of experience, I recommend always requesting video factory tours before confirming a production order. This provides genuine insight into assembly flow, machinery condition, and organizational capacity—reducing risk.

Sample Development and Lead Times

Pilot sampling helps identify structural weaknesses in design or packaging.

For most jewelry-based craft kits:

- Sample lead time: 7–15 days (including photography or logo mock-ups)

- Mass production time: 25–35 days depending on component complexity

In B2B sourcing reality, a well-structured sampling process saves considerable time and avoids costly after-shipment corrections.

Understanding Market Trends and Global Buyer Behavior

Craft kits merge creativity with convenience—a trend that aligns perfectly with post-pandemic travel recovery. As customers seek mindfulness experiences during transit, compact crafting has become an appealing retail segment. For traders and jewelry distributors, optimizing for this behavioral shift means aligning product development with both sustainability values and experiential retail marketing.

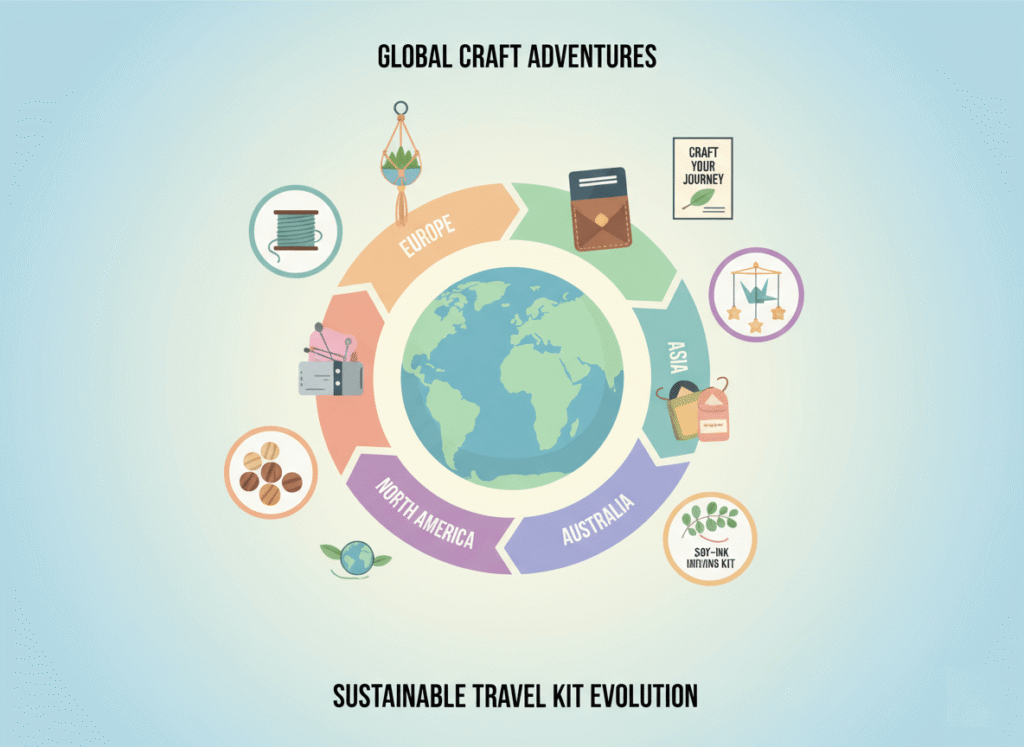

Sustainability and Eco-Conscious Design

Eco-friendly credentials are no longer optional. Buyers increasingly request:

- Recycled cord materials made from RPET yarns

- Natural beads (wood, stone, shell)

- Zero-plastic packaging

- Instruction cards printed with soy-based inks

Such elements elevate perceived value and differentiate brands in competitive eCommerce spaces.

Global Distribution Patterns

- Europe & North America: Focus on family travel craft kits, DIY jewelry projects, and creative subscription boxes.

- Southeast Asia: Emphasize space-saving, budget-oriented versions with cute accessories.

- Australia & Japan: Prioritize minimalist packaging and waterproof material selection due to climate variation.

Analyzing these behavioral nuances helps structure production calendars and seasonal collection planning.

Conclusion: Crafting Success Through Smart Sourcing

Developing travel-friendly craft kits isn’t just about creative appeal—it’s a sophisticated combination of engineering, compliance, and sourcing expertise. The most successful B2B jewelry makers understand that materials choice, compact design, and logistical agility define profitability.

Key Takeaways:

- Choose stainless steel or brass for lightweight durability.

- Design compact, resealable packaging that emphasizes safety and style.

- Follow international QC and safety standards to ensure global compliance.

- Partner with reliable OEM/ODM suppliers in China for scalable, flexible production.

- Always pilot test and visually inspect samples before full-scale manufacturing.

If you’re a jewelry wholesaler or retail brand owner seeking to launch portable DIY craft kits, now is the time to connect with experienced custom jewelry manufacturers who understand both creative vision and industrial practicality.

Request a sample kit or consultation today to explore how travel-friendly jewelry kits can become your next best-selling product.